It's main feature is to precisely count the number of capsules, lozenges, pills, tablets, and care products and fill them into bottles or packaging bags. Which can economize manpower in the packaging production process of counting and filling. Tablet/capsule counting machines can count capsules and lozenges of diverse sizes and shapes and are typically equipped with precise sensing systems, vibration bowls, dust collecting systems, etc., to ensure the efficiency and accuracy of the count. Not only raising the production efficiency but also ensuring the precision and hygiene standards of the packaging process. To the pharmaceutical and food industries, this machine is a vital packaging device.Tablet/capsule counting machines can count the number of capsules and tablets rapidly and precisely and distribute a set number of products into all kinds of packaging vessels. Speeding up the production and packaging processes efficiently and precisely through tablet/capsule counting machines.Tablet/capsule counting machines on the market can be divided into three kinds, manual, semi-auto, and full-auto. Different tablet/capsule counting machines have unique designs and working modules to meet different production requirements.

1. Manual tablet/capsule counting machines

Fully relied on manual maneuver, suitable to meet small-scale production requirements.Personnel pour tablets or capsules products onto a flat tray with holes and gently shake the tray to make the products fall into the holes. Then, remove the excessive tablets or capsules after enough shaking, when the holes of the tray are filled with tablets or capsules, the counting of product numbers finishes. Con: Slow production speed and cannot count if the products are too big or small. To change the number of products in each package, one will have to buy trays with different number of holes.

2. Semi-auto tablet/capsule counting machines

The advantage of semi-auto tablet/capsule counting machines is their ability to provide accurate product counting and efficient production, making them suitable for small or medium-scale production. In the production mode:

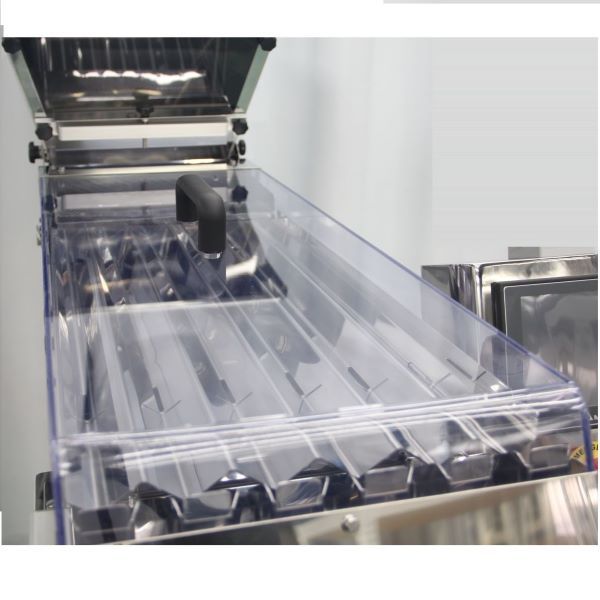

Personnel pours products into the hopper that contains a vibrating mechanism, and the hopper will send the products down the turntable. The spinning turntable will dynamically rotate the products to prevent products from overlapping or sticking to each other. When the turntable spins, the sensor will detect products and send them to their respective discharge gate, the sensor of the discharge gate will also sense accurately, ensuring the correct number of products are put into bottles or packaging bags.3. Full-auto tablet/capsule counting machines

Using cutting-edge technology to build this highly efficient and highly accurate packaging device. Require minimum manpower to mass produce and to ensure the consistency and security of products during the packaging process.After putting tablets or capsules into the hopper, they will be sent into the machine through a vibrating mechanism, then, the turntable and vibration will separate them, preventing them from sticking to each other. With the accurate counting of the sensor, the correct number of products will be sent through the discharge gate, filling bottles or packaging bags. After filling, the conveyor will carry them to the next stop to cap and label, achieving a seamless automatic production process. We own various specifications of tablet/capsule counting machines to meet different production needs. From desktop tablet/capsule counting machines (Such as TC1000 and TM1000) to full-auto tablet/capsule counting machines (Such as TC4200 and TM4600, etc.) We can provide you with a perfect solution to package products like tablets, capsules, and electronic components, furthermore, Neostarpack’s automatic tablet/capsule counting machines are flexible, as they can be adjusted to integrate with filling production lines, meeting the needs of different production scales. Not only raising the production efficiency but also ensuring the accuracy and security of medicine packaging.Our tablet/capsule counting machines can be applied in various industries, including pharmaceutical, cosmetic, veterinary, healthcare, nutritional supplement, and OEM packaging industries. Whether it is medicine, nutritional supplements, cosmetics, veterinary medicine, candies, or electronic components that you need for accurate counting, our tablet/capsule counting machines will meet your needs.

Tablet/capsule counting machines are indispensable devices to industries that pursue excellence in accuracy, regulatory compliance, and efficiency. With this technology, your production accuracy and efficiency will reach new heights.