77. What is a label dispenser? How to choose the right label dispenser that suits your production needs? The guide on how to find your perfect label dispenser.

Label dispenser is equipment that dispenses labels one at a time. By simplifying the process to peel labels from the backing papers, you may choose to dispense the labels when ready or automatically, which makes it easier and faster to stick labels to the surface of products or packages.

Commonly appear in industries such as manufacturing, food, packaging, electronics, and retail. OEM and transportation, our machines can help these industries to raise production efficiency through a simple process.

Principle of the Label Dispenser

Put the roll of labels into the dispenser and it will peel the label one at a time or continuously. The user only needs to stick the peeled labels onto the products.

Characteristics:

• Automatic Peeling:Labels automatically peel from the backing papers once you start to peel.

• Speed & Efficiency: Raising the production efficiency by speeding up the labels peeling process.

• Raising Efficiency:The automatic labels peeling hastens the labeling process and reduces the cost of manpower.

• Reduce Waste:Prevents dislocation or repetitive labeling to reduce label wastes.

• User-Friendly Design:Reduce the pressure on the hands and wrists under long working hours.

• Multifunctionality:Applicable to various label sizes and materials.

Suited Industries :

• Manufacturer : The labels on the products, components and packaging materials.

• Food & Beverage : Labeling nutrient information, expiration date and barcode labels onto food and beverage products.

• Medical Biotechnology : Medical materials, medicines and health supplement ingredients information labeling.

• Retail : Price, barcode and sales labels.

• Logistics and transportation : Transportation labels that tag packages and RFID labels.

Label Dispenser Types Can be Divided Into :

1. Manual Label Dispenser: Using a simpler mechanism, the operator pulls the backing papers to push and peel the next label.

2. Semi-Auto Label Dispenser: This type of label dispensers are equipped with sensors to detect labels and peel them from the backing papers of the label rolls and push the next label automatically.

3. Automatic Label Dispenser: Automatically label products when they pass through, these machines are usually integrated into production lines.

4. Special Label Dispenser: Dedicatedly designed for special labels such as barcode, small or transparent labels. Those special labels are more difficult to be handled manually.

How to choose the label dispenser that is best suited for our production? It requires evaluations on the following key factors to ensure the label dispenser can meet your need:

1. Label Type: Check your label type, is it adhesive label, anti-falsification label or thermal label? Distinct types of label dispensers can label diverse types of labels effectively.

2. Production Capacity: Choosing based on our production capacity, for those who need mass production, you may choose automatic label dispensers because they are capable to manage mass production. For those who have a smaller production capacity, you may choose manual or semi-auto label dispensers.

3. Label Size & Shape: Choosing the proper label dispenser based on the label’s size, shape, and material to prevent the labels from getting stuck or misalign.

4. Speed & Efficiency: Evaluate the speed of the equipment, the automatic label dispensers can provide higher speed to raise productivity.

5. Easy to Operate or not: A user-friendly designed label dispenser can reduce the interval between productions and the time to train personnel on how to operate.

6. Durability & Maintenance: Our label dispensers are made with materials with high durability, lengthening their lifespan. Furthermore, convenient to maintain and easy to replace parts or not are both key factors when choosing the right label dispenser.

7. Cost: Choosing the proper machines based on the functions needed.

The cheapest machines may have attractive prices, however, in the long-term, choosing to use high-quality label dispensers with higher durability that can save time and raise production efficiency can instead create a better profit.

Through evaluating the factors above choose a high-quality label dispenser that can optimize the production process and raise overall productivity. Neostarpack provides all types of machines for you to choose from that can satisfy the need to peel labels in various industries.

Read More:

How to label the top and bottom of salad boxes effoertlessly? Which two-sides labelers are the best?

Full Guide of the Labeling Machine: The principles of labeling, the types of labeling machines.

- Related Products

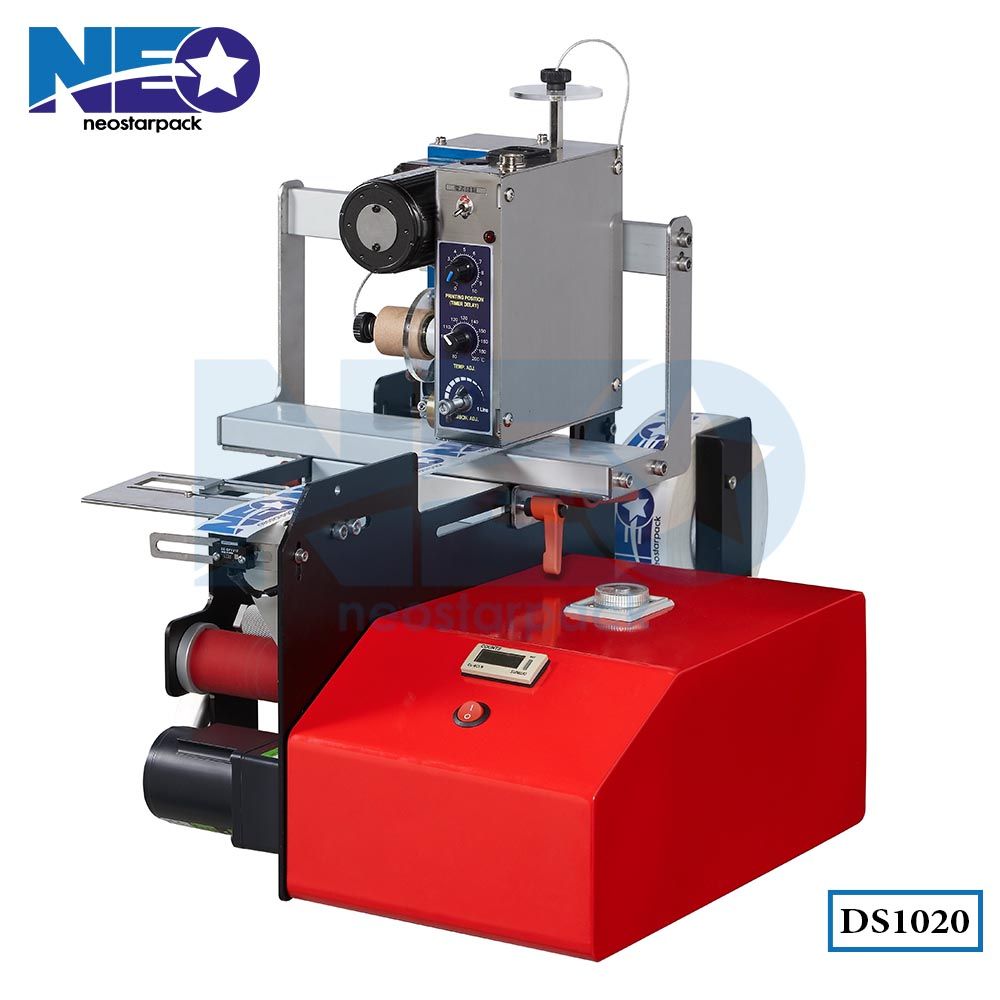

Label Dispenser With Date Printer

DS1020

Label dispenser with date printer has both label dispensing and date hot-stamping function,...

DetailsLabel Dispenser

DS1000

The label dispenser is electronic controlled. It’s simple to operate and no complicate setting...

Details