Automatic Indexing Spindle Capping Machine

CS3000

plastic bottle screw capping machine,Pneumatically driven capping machine,cosmetics bottle capping machine

Automatic indexing spindle capping machine uses the universal gripper to cap with proper torque, and it feeds straightforwardly with fast speed. Many optional types of applicators are available, and they are applicable for general plastic caps, PET caps, downward pressing caps, safe pump heads and screw caps. It can also cap special duckbilled caps, breaking through the limits of capping machines with specialized specifications.

High Efficiency Automatic Indexing Spindle Capping Machine

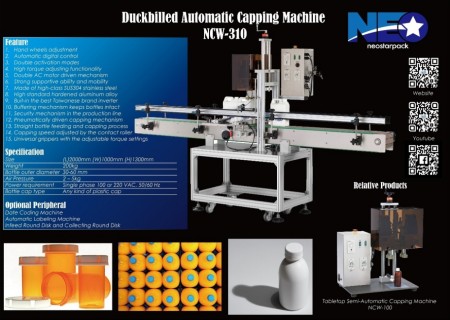

Automatic indexing spindle capper NCW-310 is the best choice for various bottles with small production. Capping height and speed are adjusted by hand wheel and speed knob easily, there is no complex parameter setting or interface. Capper will guide bottles and start capping right after caps placed by operator. The double AC motors driven automatic indexing spindle capping machine can stabilize the capping force speed. The gripping mechanism covered by rubber can avoid the mechanical impact, keeping the surface of caps intact when capping. The fine tuning automatic capping machine uses an inverter to change tightness and speed settings. The automatic indexing spindle capping machine is suitable for the industry of cosmetics, pharmacy, food & beverage to cap and seal. The mechanism design is easy to learn and to adjust for different products’ needs. It is also fitting in the needs of products with little amount but various kinds.

- Features

1. Universal grippers are suitable for any kind of caps with the adjustable torque settings.

2. High torque adjusting functionality is easy to set up and it can enhance the capping quality with no overtightening.

3. Straight bottle feeding and capping process with present production line or filling machines increases productivity.

4. Double AC motor driven mechanism has stable capping speed and force.

5. Pneumatically driven capping mechanism lifts up efficiency of conveying.

6. Hand wheels can adjust product height manually.

7. Automatic digital control can adjust according to bottle’s height, and the mechanism provides two options.

8. The contact roller on the capping machine can adjust the speed according to different bottles for a higher accuracy.

9. The best Taiwanese brand inverter helps change the tightness and stabilize the speed.

10. Strong supportive ability and mobility with wheels and stands beneath it.

11. Double activation modes of automatic the photoelectric sensor or pedal continual control with security device prevents improper operations.

12. Security mechanism in the production line can make sure the safety of operators.

13. Buffering mechanism keeps bottles intact.

14. Made of high-class SUS304 stainless steel and high standard hardened aluminum alloy, make it easy to maintain and endurable.- Specification

Bottle cap type Any kind of plastic cap capping and closing Bottle diameter 30-60 mm Air Pressure requirement 2 - 5Kg Power requirement Single phase 100 or 220 VAC, 50/60 Hz Size (L) 2000mm (W) 1000mm (H) 1300mm Weight 200kg - Option Accessories

- Infeed rotary table and Collecting round table

- Automatic Labeling Machine

- Date Coding Machine

- Automatic cap complementing machine

- Photo Gallery

- Introduce Movies

- Related Products

Automatic Dual Servo Motor Capper

NCW-415S

NCW-415S Automatic Dual Servo Motor Capper can be easily adjusted with the capping head to meet...

DetailsAutomatic Bottle Capping Machine

CS4150

Automatic bottle capping machine CS4150 integrates cap feeding, cap placing and capping functions...

DetailsTabletop Semi-automatic Capping Machine

NCW-100

The light and sophisticated tabletop semi-automatic capping machine is able to be placed in a workplace...

DetailsAutomatic Bottling Washer Filler Capper Line for Products of Viscous Liquids

NRT-100 / NBW-585 / NFP-540 / NCW-515 / NLR-300

Automatic bottling washer filler capper line integrates automatic bottle feeder, washer, filler,...

DetailsProduction Line with Automatic Counting, Filling, and Capping Machines (Counting Machines, Power Filling Machines, Capping Machines, and Aluminum Foil Sealers)

NCT-410 / NCS-300 / NCW-310

The production line of pharmaceutical level equipment with automatic counting, filling, and capping...

DetailsCounting Filling Capping labeling Line

NTC-410

Counting Filling Capping labeling Line NTC-410 suits for counting various sizes of products...

DetailsTablet Counting Filling Line

NTC-420

Tablet Counting Line NTC-420 is design for packaging regular counting materials, such as tablet,...

DetailsBottle Rinsing and Filling Machine Line

NBW-565+NFL-545+NCW-310

Bottle Rinsing and Filling Machine Line is built to help with product security and hygiene...

DetailsAutomatic Bottle Rinsing Filling and Capping Machine

NBW-565 / FG-585 / NCW-310

Fully Auto Bottle Rinsing Filling and Capping Machine This is touch screen PLC base Rotary...

DetailsAutomatic Capsule Counting Filling and Labeling Line

NTC-410+NCW-310+NLR-300

Automatic Capsule Counting Filling And Labeling Line NTC-410 suits for counting various sizes...

Details- Files Download

Automatic Indexing Spindle Capping Machine - plastic bottle screw capping machine,Pneumatically driven capping machine,cosmetics bottle capping machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Automatic Indexing Spindle Capping Machine, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.