Spindle Wraparound Round Bottle Labeler

LR4350

Wrap-around labeling machine

The spindle wraparound bottle labeling machine LR4350 is suitable for all industries that need to labels round bottle containers. The spindle wraparound labeling machine uses the method of rolling and rotating the container to stick the label tightly on the container when the bottle moving forward.

The spindle wraparound bottle labeling machine is suitable for various sizes and material bottles. The labeling machine is suitable for label itself that needs to surround the bottle product more than half a circle. The labeling method meets the need for product that required full or large surface area labeling. LR4350 has a unique labeling mode, that has high stability during product conveying and no deviation when product is labeled which provide high-precision labeling products.

Spindle Wraparound model provide better multi usability and stability

The round bottle labeling machine is popular in the market, and the LR4350 labeling machine is equipped with a pneumatic spindle wrapping unit. When labeling, the spindle roller will set the product at a fixed point and rotate to make the label adhere firmly, and it can be applied to bottles with a variety of sizes and material, such as plastic bottles, glass bottles, metal bottles, and paper containers. Spindle roller round bottle labeling machine LR4350 can wrap large and long label on the circumference of the container, which can completely cover the up to entire circle or the container. Beside round bottles and cylindrical products, it can also label product with small radian. Meanwhile, repeat labeling is a customized option for product such as beer bottles or anything that have two labels to label. The spindle wraparound labeling machine series provide highly flexible customized options, which can be configured for various label and container sizes to meet precise labeling. Other than using alone, spindle wraparound labeling machine can also collocate with a printer, automatic bottle feeding machine, outfeed turntable and packaging machine equipment into the existing production line.

Product Advantages

1. Suitable for longer and larger labels up to 100mm width and 250mm height

2. Labels can cover up to a full circle of container

3. Provide high-precision labeling

4. Independent speed adjustment for all label size between 15 ~ 30 bottle per minute

5. Apply a variety of round container and label sizes

Application & Advantage

Suitable container shape

Round bottle and cylindrical products.

Container material

Plastic, glass, metal, paper products.

Application products

Beer bottles, wine bottles, medicine cans, inhalers, eye drops, nutritional supplement bottles, essential oil bottles, cosmetics, jams, canned cereals, condiment containers, sauce bottles, all kind of cans, printer ink, gallon bottles, household cleaning products, shampoo, water filter element, motor oil, etc.

Industry

Pharmaceutical industry, food and beverage industry, chemical industry, biotechnology industry, cosmetics manufacturing industry, groceries industry, technology industry, etc.

Label types

Self-adhesive labels, anti-counterfeit labels, tamper-evident labels, instruction labels, laser labels, computer labels, fragile labels, medicine bottle labels, beer labels, wine bottle labels, transparent labels (requires transparent label electric eye)

Labeling range

Round and cylindrical container surface area is pasted in a wrap-around method, the label all wraps around the bottle container a full circle, 3/4 circle, 1/2 circle or any part of bottle.

Labeling method

Spindle wraparound labeling.

- Features

1. Spindle wraparound module design, high labeling precision

2. Configure the width of different labels

3. The human-machine interface can save 20 sets of production parameters, which can be read with one key, without the need to recalibrate the same label, which speeds up the production conversion time.

4. Actively detect label breaks, or run out of labels, and will stop production on its own to maintain the quality of complete products.

5. Equipped with colored HMI display touch screen, it is easy to input production parameters when operating the machine, which is simple and easy to operate.

6. Unique digital labeling parameter design, which can be fine adjust to meet the needs of different labeling positions.

7. Intelligent troubleshooting system to guide the operator to solve the difficulties of the labeling process step by step

8. Automatic labeling counter, real-time monitoring of production capacity status through the touch panel.

9. Smart memory function, the last parameter is automatically provided when the machine is turned on, and the production can be launched immediately without setting it again after the machine is turned on.

10. The labeling speed and product conveying speed can be adjusted to improve labeling efficiency.

11. The labeling position and angle of the product can be fine adjust directly on the labeling applicator

12. Automatic bottle spacer module to keep the distance fixed between bottles to make labeling smoother

13. PLC is equipped with touch human-machine interface, any malfunction information will be provide in real-time.

14. It can be produced as a single machine, or collocate with other machines into automatic production line.

15. The encoder tracks the production speed synchronously, maintains a constant production rate and monitor the production capacity in real time.

16. Photoelectric sensor, automatically detects and locates the product to adjust labeling position easier

17. Accurate positioning and speed control of the stepping motor to achieve high precision and high stability labeling.

18. Automatic guidance mechanism, which automatically channel the product to prevent the production line from being blocked, and the label can accurately labeled to the preset position

19. The low-friction conveyor belt transports products stably and does not damage the products.

20. Optional high-grade conveyor belt, in line with MCC food hygiene standards.

21. The machine is made of SUS#304 stainless steel and high-level aluminum alloy, which conforms to GMP standards and is easy to maintain

22. A wide range of applicable products, convenient for customer that have multiple products for simple operation for product replacement.

23. The labeling machine is manufactured in Taiwan from design to manufacturing. The quality and service are perfect.

24. Japanese-made sensor synchronously and automatically detect positioning to achieve high-precision labeling.

25. The label length is simple to set, directly input the required length, no need to use tools to adjust.

26. Optional from step motor or servo motor to meet the production requirement to increase production efficiency.- Specification

- Automation level: fully automated

- Machine motor: stepper motor or servo motor

- Labeling speed: 15~30 pieces/minute (according to label size)

- Labeling accuracy: +/-0.5~1mm (according to the product)

- Bottle size: (D) 16-90mm (H) 30-160mm

- Label size: (W) 10-100mm (L) 20-250mm

- Label roll size: (ID) 75mm (OD) 280mm

- Product size: (W) 10-100mm (L) 20-250mm

- Power supply requirements: 110 or 220VAC, 50/60Hz, single phase

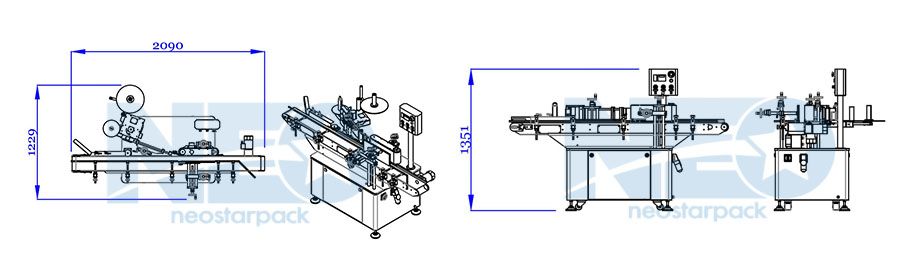

- Machine specifications: (L) 2090mm (W) 1230mm (H) 1350mm

- *Specification may vary depending on configuration, detailed specifications are subject to actual shipment.

- Option Accessories

- Date coder

- Transparent label sensor

- Bottle spacer module to ensure equidistant transportation of products

- High-level servo motor

- Advanced functions of HMI human-machine interface: permission setting, production history, etc.

- Infeed and outfeed turntable (motor driven)

- Customized lengthened conveyor belt

- Partial can be design according to the special specification from customers to customized unique labeling machine

- Introduce Movies

- Related Products

Automatic Round Bottle Labeler

LR3000

Automatic round bottle labeler LR3000 is suitable for food, pharmaceuticals, beverage, and cosmetic...

DetailsExquisite Cabinet Free Set Round Bottle Labeler

LR2100

Free set round bottle labeler LR2100 can be widely used in labeling cosmetics, food, beverage...

DetailsWrapping Around Labeler

LR2300

Wrapping around labeling machine LR2300 compact design with high mobility for labeling round...

DetailsAutomatic Round Bottle Labeling Machine

LR4000

Automatic round bottles labeling machine LR4000 is available for any kind of erective plastic...

DetailsAutomatic Round Bottle Labeler with Rotary Table

LR4300 / RT1080 / RT2080

This is the most convenient labeling machine with high stability and precise position. It has an automatic...

Details

Spindle Wraparound Round Bottle Labeler - Wrap-around labeling machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Spindle Wraparound Round Bottle Labeler, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.