Tabletop Top Labeler

LT1100

Tabletop top labeling machine

Our LT1100, tabletop top labeler works with high efficiency, while provides perfect labeling results at the same time. The tabletop top labeling machine comes with a brush and sponge roller to smooth labels, which helps to achieve the excellent labeling result. Our top labeler is compact in size, easy to move, and the best suit for small batch production. You can easily set parameters through the microcomputer control interface without complicated procedures. Moreover, the user-friendly interface allows our clients to familiar with the operation easily. The highest labeling speed is up to 3600 pcs/hour.

Widely used in various industries and products

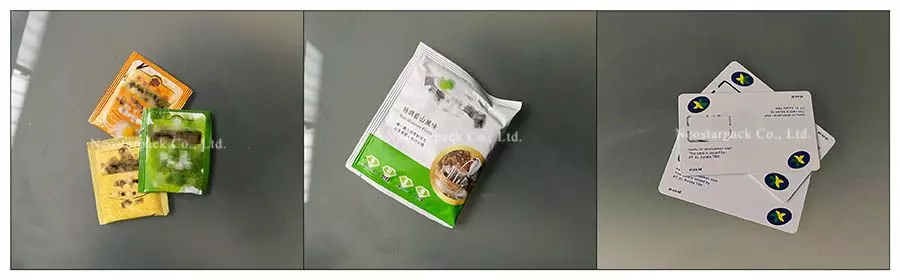

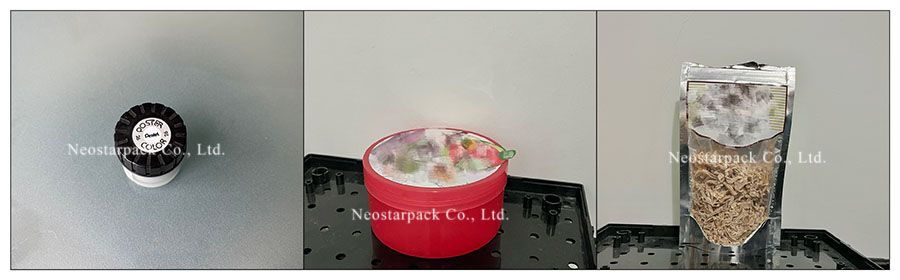

Our table top label applicator machine is not only suitable for general products you may see at the store, but packaging from various industries, such as precooked meals, bakery boxes, medicine boxes, facial masks and cosmetics products. There’s a growing need for using food delivery platform to order meals during the pandemic time. More disposable packages have been used, such as paper cups, lunch boxes, cakes boxes, zipper bags, and plastic bags. The flat surface label applicator LT1100 is the best choice to apply labels onto your product cost-wisely.

Unlike round bottle labelers, LT1100 flat label applicator attaches stickers on the top, side or bottom of the product. And it’s not limited to flat containers, for example, the top of caps, the bottom of plastic cups, boxed snacks and gift boxes which are common products in our daily life are all applicable.

High production efficiency and economic benefits improve customer market competitiveness

Manual labeling is difficult to achieve accuracy and fast production. You can easily avoid human errors and improve production efficiency by using our label applicator for flat surfaces. Our LT1100 have no complicated setting procedures so it’s easy to operate. This labeler is equipped with high-precision sensors, gives you high productivity with accurate labeling results, thereby strengthen your capacity and market competitiveness.

Neostarpack provides customers with valuable labeling solutions and maximizes the interests of our clients from our many years’ experience. Our labelling equipment and bottle filling packaging machines are people-oriented, which emphasize in versatility, flexible convenience, simple operation, and cost reduction. We believe that we can satisfy all customer requirements though integrated solutions and outstanding production lines.

Advantages:

- The tabletop labeling machine is convenient to move around and space-saving.

- It can be operated by a non-professional with easy procedures.

Operators can adjust label applicator position by a lever. The label length is set directly with touch-tone design buttons. - The sticker applicator machine is shipped with sensors from well-known brands. It provides fast, accurate, and high-quality labeling.

The machine can smooth stickers by the brushes or a sponge roller to make labeling results more refined. - LT1100 desktop label applicator can combine with our other machines to build an automatic production line.

e.g., card feeder, bag feeder, date coder, and transparent label sensor. - High efficiency enhances the production capacity and market competitiveness for customers.

Application & Advantage

Suitable goods

Cosmetics, Facial mask, Almond chocolate, Candy box, Dried fruit, Cereal, Family size potato chips, Tea bag, Drip coffee, Coffee bean, Food delivery box, Paper cup, Frozen food, Animal feed, Cake box, Dish soap, Laundry ball, Soda power, Wet wipe Duster sweep sheet, Poster paint, Hard card, Memory card, Card, Album, Envelope, Automotive parts, Screen protector, Notebook, Kraft paper, Zipper bag, Spout bag, Aluminum foil bag, polypropylene (PP) plastic bag.

Suitable container shape

Most are suitable for flat products with top labeling, which usually paste labels on the top, side or bottom of containers.

Suitable container material

Paper, Glass, Aluminum foil, Zipper bag, Plastic (PP, PE, PET), Metal (tinplate, aluminum can).

Suitable labels

Ingredient Labels, barcode stickers, anti-counterfeit labels, promotional labels, waterproof stickers, transparent stickers, laser security label, fragile labels, security labels, self-adhesive labels.

Labeling style

Attach the stickers on the top of the product while the product pass through the label applicator. Next, the peel plates and brushes will make sure the final product is intact with no wrinkles or bubbles.

Suitable industries

Machinery manufacturing, Cosmetic industry, Food processing/manufacturing industry, Bakery industry, Pharmaceutical industry, Catering industry, Electronic product industry, etc.

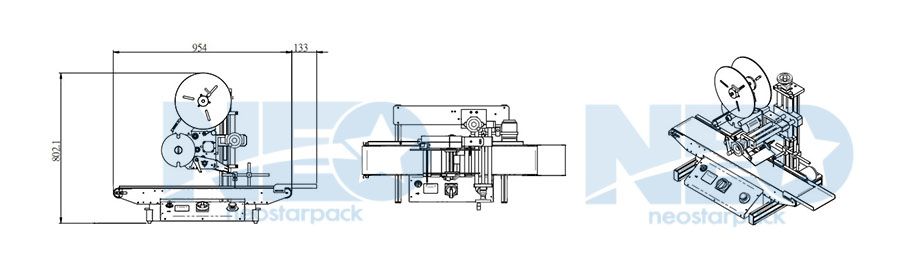

Machine Layout

- Features

1. High-quality labeling

The sticker applicator machine is equipped with Japanese sensor which makes labeling fast and precise. Production with top labeling, use smooth label components to ensure the finished products are beautiful without wrinkles.

2. Operation method is simple

User-friendly interface like hand wheel adjustment and touch-tone design can not only eliminate complicated setting procedure, but avoid the loss caused by human error. Company can reduce education training for their employees as well.

3. The label applicator, which its height and angle can be adjusted, it’s driven by an automatic stepper motor. The labeling process is stable and precise.

4. Wide-ranging of labeling products, suitable for different self-adhesive labels in various industries

Labeling is not limited to flat products, but also applied to the top, side or bottom of three-dimensional products.

5. The desktop label applicator machine saves time and space

One table can start production because it’s small-in size with high mobility.

6. The conveyor belt is made of PVC which is high coefficient of friction, It's smooth and durable.

The conveyor belt can be adjusted its speed flexibly based on customer requirements.

7. LT1100 tabletop labeler can combine with our card feeder, bag feeder, date coder as a production line to save labor costs.

8. Made of SUS#304 stainless steel and aluminum alloy

The tabletop top labeler is firm and durable; besides, it’s easy to maintenance.- Specification

Labeling Speed

30-60 pcs/min (depending on label size)

Label Size

Length 10-300 mm; Width 10-100 mm

Label Roll

Inner Diameter 75 mm; Outer Diameter 300 mm

Machine Size

(L) 950 mm × (W) 580 mm × (H) 730 mm

Accuracy

± 1 mm

Power Supply

110/220 VAC; 50/60 Hz

※Actual product specifications may vary

- Option Accessories

- Card feeder

- Bag feeder

- Laser coder

- Date coder

- Transparent label sensor

- Photo Gallery

- Introduce Movies

- Related Products

Tabletop Automatic Top Labeler

LT1000

The Tabletop automatic top labeler LT1000 is an economic, budget friendly piece of machinery...

DetailsTabletop Two-Sided Labeler (with two label applicator)

LT1252

Tabletop two-sided labeler LT1252 is designed specifically to fulfill labeling tasks with high...

DetailsTabletop Wrap Around and Top Labeler

LR1300 / LT1100

Equipped with a round bottle labeling head and a top labeling head, wrap around and top labeling...

DetailsLabel Applicator

LA1000

A label applicator plays an important role in a labeling machine, it is the heart of a labeler....

DetailsTabletop Bottle Labeling Machine (Standard Model)

LR110A

Our tabletop round bottle labeler can make all kinds of round bottle labeling job done with...

DetailsTabletop Round Bottle Labeling Machine

LR1000

Tabletop round bottle labeling machine LR1000 is very suitable for small and medium manufacture...

DetailsTop Tamp Labeler (Top Tamp Labeling Machine)

LS1200

Top tamp labelers LS1200 is space-efficient. Each part of it comes in high standard. Its high...

DetailsTabletop Tamp Labeler

LS1000

LS1000 Tabletop tamp labeler is powered by step motors, which produce stable labeling outputs....

DetailsCompact Filling Line (Filler / Capper / Labeler)

Semi-automatic star wheel capper is the best solution of automatic filling line for flexible...

DetailsFriction Feeder

CF1000

The Friction feeder CF1000 is designed to be feed sheets or cards, continuously to an existing...

DetailsAutomatic Card Feeding Machine

CF1100

Automatic card feeding machine is designed to be feed cards, bags, or sheets continuously that...

Details

Tabletop Top Labeler - Tabletop top labeling machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Tabletop Top Labeler, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.