Automatic Top and Bottom Labeler

LW3000

Top & bottom labeler

LW3000 is a widely used labeling machine, which can paste labels at the top and bottom of the product at once. This two-in-one functionality makes it more efficient compared to traditional one-way labelers. The greatest advantage of the LW3000 lies in its ability to combine the strengths of both top labeling and bottom labeling machines. The LW3000 is designed to be easy to use, versatile, and high flexibility to provide top labeling or bottom labeling.

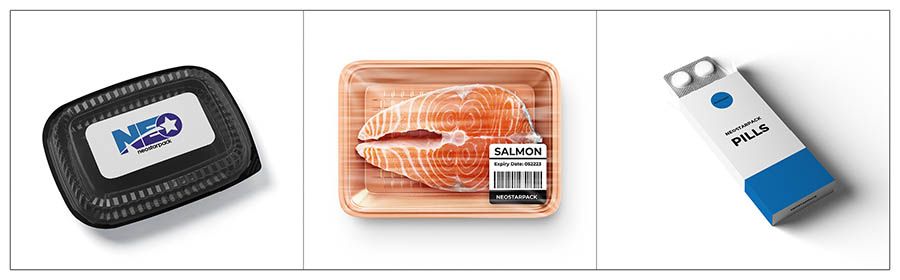

LW3000 is often used in product appearance labels, such as: promotional labels, ingredients, batch numbers, nutrition fact, etc. Meanwhile, it can also be used in secondary packaging, such as outer packaging of cartons.

One labeling machine gets two labeling benefits, improving the capacity

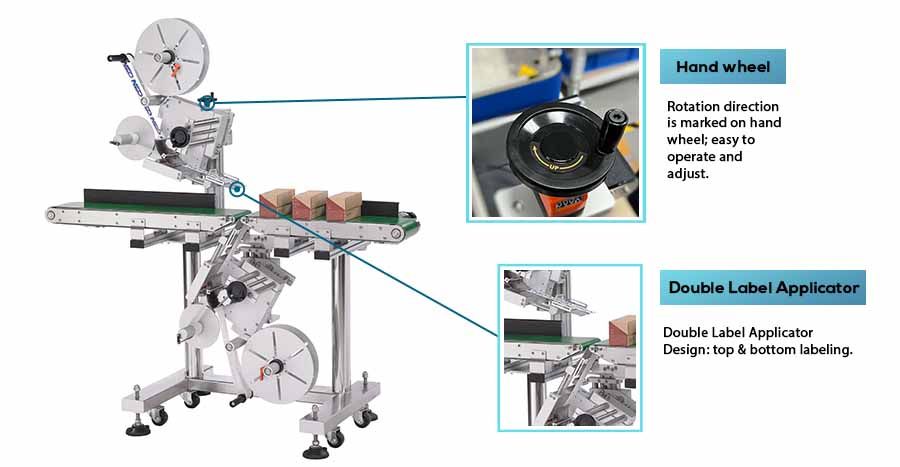

The labeler equips two label applicators, one for the top labeling, and another for bottom labeling. When the product or container passes through the conveyor, this dual-labeling capability can apply both top & bottom labels simultaneously, thereby accelerating the labeling process. The top labeling and the bottom labeling are implemented by different systems.

The top labeling: Putting products on the conveyor and attach stickers on products from above while products pass through the label applicator.

The bottom labeling: The product is usually positioned by a calibration unit, and attach labels from the bottom.

Pasting two labels at the same time can reduce operations of duplicate feeding, labeling and smoothing labels, in turn increasing production capacity.

Flexibly combine different modules, widely connect to different packaging machines

Labeling machin LW3000 is high accuracy and fast, which can adapt to different sizes and shapes of product and label with high-speed and precise labeling. Because it is equipped with an advanced control system, it can ensure the labeling quality, and can be easily connected with other packaging machines to establish a flow production.

If there are any mass production needs, please fill in the form below, we will contact you as soon as possible, and provide you the most suitable labeling solution and complete production line planning.

Advantages:

- High productivity & efficiency:

Attaching stickers to the top and bottom of the product at the same time to speed up the labeling process in manufacturing and packaging. - Flexibility

Allow to install the machine in any location flexibly according to production needs. - 2 in 1 labeling style

It's suitable for different products and has the advantages of both top and bottom labeling machines. - Easy to connect with any type of production line.

- Save-space

Half the footprint compared to two separate labeling machines.

Application & Advantage

Suitable Goods:

Food & Beverages: Various container of food and beverages (can, bottle, box, bag).

e.g. : Juice, soda, water, sauce, frozen food, meat, snack, cereal, ham, cheese, coffee, tea bag, herb tea, foil bags, condiments and spice jars.

Nutritional supplement: Vitamin C, Lutein or medicine.

Care Product: Lotion, Essence oil, facial mask, shampoo, conditioner, cosmetics

Daily Necessities: Detergent, Cleaning supplies, Air Freshener, Dental floss.

Electronic Products: Parts of phone and computer, electric parts, SD card, DDR.

Industrial Products: Chemicals, Parts of vehicle, Engine oil.

Suitable Product Shape:

The labeled part should be flat and smooth surface, and labeling positions are at the top and bottom of products. Single-side labeling.

Suitable Product Material:

Paper, glass, aluminum foil, plastic (PP, PE, PET,PVC), metals (tinplate, aluminum, stainless steel).

Suitable Labels:

Self-adhesive labels, Promotion labels, Anti-counterfeiting label, Laser security label, transparent labels, bar code, fragile stickers, ingredient fact, polyester sticker, Serial number stickers.

Labeling Style:

There are 2 label applicators; one is for top labeling; another is for bottom labeling. While products pass through the label applicator, automatically pasting labels at the top and bottom of products at the same time. Then use brushes and sponge rollers to smooth the sticker on the product to ensure the final product is well labeled.

Suitable Industries:

Pharmaceutical industry, Food industry, Catering industry, Cosmetic industry, Biotechnology, Manufacturing Industry, Daily chemical industry, Electronic product industry, etc.

Machine Layout:

- Features

1. User-friendly operation interface

2. The labeler is applicable to different size, shape, and material of container. It’s a versatile labeling solution that suitable for many products.

3. Attaching 1 label or 2 labels depends on customer needs.

4. Make sure the stickers are pasted on top and bottom of products precisely by advanced sensor and program. Brilliant performance in accuracy and speed.

5. PLC control touchscreen:

allowing take control of labeling and the capacity.

6. Simplify memory parameter function

Save the different parameters, breaking through traditional time-consuming repeated testing, saving adjustment time when changing products.

7. Large-size conveyor design:

It’s suitable for different size of production; multiple products share one machine.

8. According to the features of products, choose and fine-tuning the labeling position with convenient hand wheel.

9. The machine is shipped with E.M. Stop button. High security; If there is any error, you can stop the production at any time.

10. The machine is combined with modular systems, which can be customized to adapt to different product specifications.

11. Standard module design:

The labeler is firm, durable and easy to maintain.

12. It can connect with existing filler, capper, date coder and collecting machines to build a production line to reach mass and fast production.

13. It equips with a label counter; the output of labelling production will display on the screen.

14. According to customer needs, providing different conveyors which can be widely used in many industries.

15. Stepper motor labeling module:

long-time stable production with high efficiency

16. Adjustable double label applicator module:

fine-tune the angle and height of label applicators according to the product size

17. Hand wheel with number position indicator

display the set parameter of labeling

18. According to the difference of products, the labeling speed is 1,800-4,800 pcs/h

19. The machine is made of high-grade SUS# 304 stainless steel and aluminum alloy, which meets the hygienic standards.- Specification

Motor

Stepper Motor

Labeling Speed

30-80 pcs/min (according to product and label size)

Accuracy

± 1mm

Label Size

(Width) 10-100mm, (Length) 10-250mm

Label Roll

Inner Diameter 75 mm; Outer Diameter 300 mm

Power Supply

110 or 220 VAC, 50/60 Hz, single phase

Conveyor

200mm (customize available)

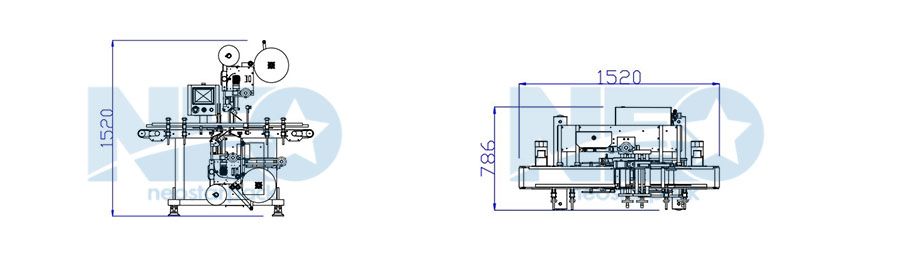

Machine Size

(L) 1520mm x (W)700mm x (H)1700mm

※ Actual product specifications may vary

- Option Accessories

- Transparent label sensor

- Japanese servo motor; labeling speed: 40m/min

- PLC system

- Collecting machine

- Smoothing unit: sponge rollers and brushes

- Card Feeder, Bag Feeder

- Date coder, Laser printer, Inkjet printer

- Introduce Movies

Automatic Top and Bottom Labeler - Top & bottom labeler | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Automatic Top and Bottom Labeler, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.