Semi-Auto Bottle Rinser

BW2000

Bottle washing and rinsing machine

Bottles are common containers in various industries that serve the purpose of containing products such as food, beverages, medicine, and cosmetics. To ensure the hygiene and quality of products, the bottles must be cleaned thoroughly. The cleanliness of the containers is the basic hygiene standard that affects both the products' quality and the client's trust. Semi-auto bottle rinser is the essential equipment in the filling and packaging process, credit to their capability to clean bottles in various sizes rapidly and efficiently, ensuring the bottles achieve hygiene standards before filling the product.

BWT2000 semi-auto bottle rinser can clean both the inside and outside of bottles simultaneously with high efficiency. BWT2000 applies to many kinds of bottles, no matter if it is standard bottles, tall bottles with narrow necks, hard-to-wash bottles, or dusty bottles. Our machine is suited for industries such as pharmaceutical, food, winery, brewing, biotechnology, or laboratory and glass manufacturing factories.

Semi-Auto Bottle Rinser: The key item to protect the product quality of industries and ensure hygiene.

Semi-auto bottle rinser BWT2000 provides an ideal solution to clean bottles for industries such as brewing, winery, food, pharmaceutical, biotechnology, and cosmetics. BWT2000 not only can uses water or sanitizer to clean bottles but also can be custom-made to clean recycled bottles based on product needs. Semi-auto bottle rinser BWT2000 is equipped with 12 streams of wide-angle rinsing water, which are designed are clean the interior of containers. On the exterior, the machine is equipped with rinsing nozzles which can effectively remove stains on the exterior of the bottles, ensuring the containers are both clean and clear inside out. Furthermore, the dedicated blowing process can effectively decrease any remaining water on the containers after rinsing.

BWT2000’s rinsing process can be set based on each bottle’s size and degree of dirtiness. One may freely adjust the container’s interior and exterior rinse time to not only raise efficiency but ensure each bottle is as clean as a whistle.

Our bottle rinsers are small, but they stand tall with high efficiency

Semi-auto bottle rinsing machine BWT2000’s strong rinsing capability and compact size made it the top choice for all industries. It was dedicatedly designed for small batches production; thus, the machine size is within one square meter, and it holds six bottles at the same time. Reducing the workforce needed to rinse the bottles while making it more convenient for personnel to take the bottles. If a large batch is needed additional rinsing nozzles can be added or an advanced automatic model is also an option to reduce rinsing frequency and raise the efficiency further.

It is necessary not to damage the glass containers during the rinsing process. BWT2000’s rinsing tank is equipped with custom-made stainless steel racks based on each bottle sizes, it helps stabilize the loaded bottles and prevent them from being damaged. Furthermore, the bottle rack can be disassembled and replaced rapidly. You may continue to use BWT2000 in the future for different bottles, increasing the application range of the machine.

BWT2000 is a revolutionary bottle rinser with the advantages of high efficiency, convenience, and safety, making it the essential production equipment for all industries. Providing a faster and more hygienic production process while decreasing labor costs, our machine will let your products meet a higher level of quality standards.

Advantages of Our Bottle Rinser

1. Low water consumption, save water with high efficiency: Each rinsing process requires only 7 liters of liquid, which can be water, detergent, or sanitizer. This machine can save resources while being eco-friendly.

2. Wide-angle high-pressure water make bottles as clean as a whistle: High pressure water rinsing, thoroughly cleaning the interior and exterior of bottles without a blind spot. Meet the high rinsing standards of brewing, pharmaceutical, and refined chemical industries.

3. Compact size, space-saving design: The bottle rinser is designed to be compact, taking little space, and easy to install. Suitable for various production environments.

4. Wide opening design, convenient to operate: Convenient to place or take bottles, and easy to rinse.

5. Custom-made racks to protect the bottles:Stainless steel racks are dedicated for stabilizing bottles during rinsing and to reduce the risks of colliding, scratching, or cracking bottles, prevent additional costs.

6. High standard cleaning, hygiene, and safety: Meeting hygiene standards to ensure the cleanness of interior and exterior of the bottles, suitable for all the industries with high hygiene requirements.

Applicable products:

Winery Industry: The packaging bottles of alcoholic beverage bottles like red wine bottles, white wine bottles, Japanese sake flasks, whiskey bottles, champagne bottles, beer bottles, fruit wine bottles and gin bottles.

Food Industry: Various food packaging related bottles such as soy sauce bottles, salad dressing bottles, juice bottles, edible oil bottles, vinegar bottles, seasoning bottles, jam bottles, honey bottles, olive oil bottles, water bottles, carbonated beverage bottles, sports drink bottles, tea bottles and other beverage packaging bottles.

Pharmaceutical: Medicine packaging bottles, vials, oral liquid bottles, capsule bottles, eyedrop bottles, nasal spray bottles, dropper bottles, ampoules, powder bottles and mouthwash bottles, etc.

Health Food: Health supplement bottles, vitamin bottles, protein powder bottles, fish oil bottles, probiotic powder bottles and energy drink bottles, etc.

Biotechnology and Laboratory: Laboratory containers, culture bottles, Petri dishes, reagent bottles, sample vials, test tubes, biological reagent bottles, graduated cylinder, and glass beakers, etc.

Glass Bottles Manufacturer: Various glass bottles, narrow mouth glasses, wide mouth glassed, wine glasses, glass cups, beakers, measuring glasses, etc.

Cosmetics: Cosmetic containers, perfume bottles, essence bottles, lotion bottles, face cream bottles, toner bottles, etc.

Applicable Containers: Glass bottles and glass containers.

Applicable Container Shape: Round bottles, square bottles, narrow mouth bottles, wide mouth bottles (Customizable.)

Applicable Rinsing Liquid: Clear water, disinfectants, detergents, etc.

Rinsing Speed: 20 to 30 seconds per rinsing process (Based on settings and containers condition.)

Operation Process of Semi-Auto Bottle Rinser BWT2000

1. Invert and place the bottles onto the bottles stands of the rinsing tank, and make sure each bottle is placed steadily.

2. Close the lid of the rinsing tank, and make sure the lid is completely sealed to prevent any splash during rinsing process.

3. After pressing the rinsing switch, the machine will automatically perform the rinsing process based on the rinsing settings set by you.

4. After rinsing is completed, the machine will make buzzing sounds (Beeping sounds) to remind the operator to take the rinsed bottles out.

5. Maintenance Method:

• Regularly clean the water stains: To maintain the best performance of the machine, we recommend cleaning the water stains regularly.

• Rinsing tank’s lid cleaning: The rinsing tank’s lid can be disassembled to clean, ensuring the hygiene of each rinsing process.

Applicable industries:

Pharmaceutical, food and beverage, chemical, electronics, clothing and textile, biotechnology, household chemicals, cosmetics and toy industries.

- Features

1. Increasing production efficiency, based on your setting of the rinsing time, the machine can rinse 8 to 15 bottles per minutes, which is the efficiency of 2 to 3 manual rinsing workers, greatly raising production efficiency.

2. High efficiency rinsing, strong rinsing feature to clean the interior and exterior of the glass bottles at the same time, ensuring each and every corner is clean, without a blind spot.

3. The machine is applicable to narrow mouth bottles, dedicatedly designed for narrow mouth and long bottles that are difficult to rinse the interior. This is to ensure both the interior and exterior of bottles can be rinsed completely clean.

4. Applicable to various industries, no matter it is industries such as brewing, biotechnology, laboratory or glass bottle manufactory, our machine can utilize water or disinfectants to rinse the bottles completely, react or all kinds of rinsing requirements with flexibility.

5. Equipped with wide-angle streams of rinsing water to rinse every corner of the glass bottles to ensure complete cleanness.

6. Equipped with 6 interior nozzles and 6 exterior nozzles, cleaning the bottles inside out without a blind spot.

7. Installed with air-blow feature to prevent water residual and increase the rinsing effect.

8. Compact machine size, easy to install and suitable for various production environments, effectively utilize the production space.

9. Adjustable rinsing cycles depends on bottle sizes and dirtiness.

10. Each rinsing cycle only consume 7 liters of liquid, saving resources while being eco-friendly.

11. Meet the high rinsing standards of pharmaceutical, and refined chemical industries, ensure the products meet the need of high hygiene standards.

12. Installed with detachable stainless-steel bottle racks within the rinsing tank to place the bottles steadily and to protect the bottles from being damaged or cracking.

13. Designed with a wide opening to make the bottles easier to take while reducing risk of collisions and making the operation more convenient.

14. Detachable rinsing tank cover, can be detached and cleaned, made by high quality stainless steel SUS304. Durable and easy to maintain.

15. Installed with safety sensor that will prevent the activation of rinsing when the cover is not securely closed to ensure operational safety.

16. Under running status, if the cover accidentally opened, the machine would stop immediately to prevent accidents.

17. Reminder function: Equipped with buzzer that will remind the operator to retract the bottles after the rinsing to ensure a smoother production process.

18. Equipped with an emergency stop button: Safeguards the operations and let you operate with peace of mind.

19. Equipped with foot pedal switch, to raise production efficacy.

20. Easy to operate, no special training needed to use our semi-auto bottle rinser.

21. Bottle racks can be expanded based on production needs, easy changing between different bottles.- Specification

- Rinsing Nozzle: 6 interior rinsing nozzles and 6 exterior rinsing nozzles

- Rinsing Method: Liquid rinsing

- Degree of automation: Semi-auto

- Rinsing Speed: 20 to 30 seconds per rinsing process

- Applicable Liquid: Water, disinfectors, and detergents.

- Applicable rinsing containers: Glasses, beakers, and glass cups (Can be customized for other containers)

- Power Supply: 110 or 220VAC, 50/60Hz, single phase

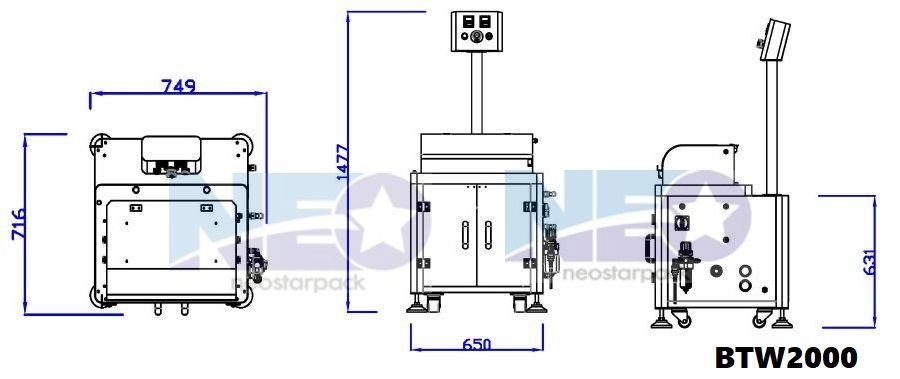

- Machine Dimension: (L)720mm (W)750mm (H)1500mm

- Liquid infeed and outfeed position: On the right side of the machine (Hose length customizable)

- Manufacturing Location: Taiwan

- Warranty Period: One year

- ※ Dimensions may vary based on configurations; actual specifications are subject to the machine received.

- Option Accessories

- Washing Module

- Introduce Movies

- Related Products

Automatic High Speed Bottle Washing Machine

BW5400

The automatic high speed bottle washing machine can work for many types of bottles at the same...

DetailsAutomatic Bottle Rinser

NBW565

Automatic bottle washing machines have steel gripping holders to flip the bottle and to clean...

DetailsAutomatic Bottle Rinsing Filling and Capping Machine

NBW-565 / FG-585 / NCW-310

Fully Auto Bottle Rinsing Filling and Capping Machine This is touch screen PLC base Rotary...

DetailsBottle Rinsing and Filling Machine Line

NBW-565+NFL-545+NCW-310

Bottle Rinsing and Filling Machine Line is built to help with product security and hygiene...

Details

Semi-Auto Bottle Rinser - Bottle washing and rinsing machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Semi-Auto Bottle Rinser, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.