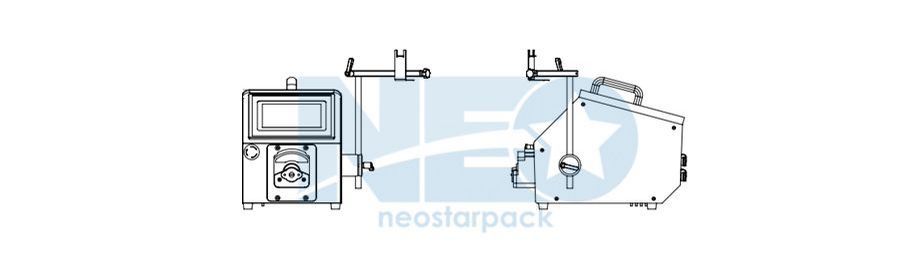

Tabletop Peristaltic Pump Liquid Filling Machine

FT1000

peristaltic pump liquid filler

The FT1000 Tabletop Peristaltic Pump Liquid Filling Machine features precise, hygienic filling and is suitable for industries such as biotechnology, food, chemical, and medical, as it allows for filling with no chance of contamination. It's lightweight and portable, takes up little production space, and is perfect for those who are starting to move into automatic production, those who do not have a lot of extra production space, or those who would like a backup machine to support an existing production line.

The interface allows up to 20 recipes to be saved at once, for those who are constantly switching products, and also allows the operator to keep track of production levels. Only one operator is needed during production, which frees up valuable manpower to focus on other tasks.

The one-tube feature of this filling machine allows the user to switch between production lines without fear of cross-contamination.The liquid does not leave the tube at all during the filling process, saving time and energy that can be spent more productively. For products that may need to be filled in a sterile environment or those that may have chemical reactions to the metal innards of a typical filling machine, this will reduce all sorts of unwanted exposures and possible hazards. For products where isolation and sterilization are not high priorities, this machine can still help save cleaning time as there is no need to clean the machine's main body. Only the tube needs to be cleaned, and a different tube can be assigned to each product, so that product switching can be done just by putting the assigned tube onto the machine. So for our consumers that need to switch between three or more products, or have high hygiene standards, we recommend the FT1000 filling machine for your filling needs.

Advantages

1. Steady and precise filling by the peristaltic pump.

2. Single tube means that there is no possibility of cross-contamination, as well as easy production switching.

3. No additional parts or tools needed to change production.

4. Meets the cGMP Guidelines for Good Manufacturing Practice for Medicinal Products.

5. Can be used with a capper and labeler to create a semi-automatic production line.

Application & Advantage

Suitable for

Syrups, sauces, oils, yogurts, juices, glues, chemicals, alcohols, creams, shampoos, detergents, pastes, serums, concentrates, extracts, nail polishes, pigments, varnishes, slurries, resins, inks, purees.

Suitable fields

Pharmaceuticals, biotechnology, dietary supplements, cosmetics, food and beverages, laboratories, hospitals.

Q & A

Q:Can fillings with solid chunks be used with the FT1000?

A:It is not recommended. For solid/liquid mixes, we recommend taking a look at the FP line, which can fill those kinds of liquids.

Q:What's the difference between the FT1000 and FG1000?

A:Visually, they appear very similar to each other. The most crucial difference is in the way they pump liquids. The FG1000 uses a gear pump, which means that the infeed and outfeed tubes are connected to the gear pump in the front. As the liquid passes through the gear pump, it is pushed towards the outfeed tube. The FT1000, on the other hand, features one unbroken tube that goes from infeed to outfeed. The peristaltic pump massages the tube to force the liquid to pump through. The FG1000 is can fill continuously, while the FT1000 fills in cycles and is suitable for products that need to be filled in a sterile environment.

- Features

1. Features a humanized digital control interface, adjustable filling volumes, speed, and intervals for easy adjustments

2. User-friendly PLC program, making operation fast and easy.

3. Semi-automatic operation means that the machine has no complicated parameter settings; it's easy to use even for first time operators.

4. It is equipped with food-grade silicon filling tubes, meeting the highest sanitary requirements.

5. It has an emergency stop button to protect the safety of operators.

6. Liquids run through switchable tubes only, providing easy clean up without the need for disassembling the machine itself.

7. Adjustable filling volume, speed, and interval time provide high filling flexibility. Connectable to a foot pedal; can be operated either by hand or foot.

8. Switchable filling tubes. Each can work with one kind of liquids, eliminating the possibility of cross-contamination.

9. Solid-body design provides high stability and durability.

10. Small in size, providing space efficiency and mobility.

11. The tabletop peristaltic pump filling machine FT1000 works best with liquids under 60 degrees Celsius.

12. It is made of SUS 316 stainless steel, meeting cGMP level sanitary requirement.- Specification

- Filling range: 5~500ml

- Filling speed: 5-50ml/sec

- Filling accuracy: ±0.5%~1%

- Power supply: 110 or 220VAC; 50Hz/60Hz; single phase

- Machine dimension : (L)459.7mm(W)493.4mm(H)419.1mm

- Option Accessories

- Automatic pneumatic shut-off valve.

- Diving filling nozzle

- Customized stainless steel hopper

- Electrical scale

- Introduce Movies

- Related Products

Tabletop Gear Pump Liquid Filling Machine (tabletop filling machine)

FG1000

Tabletop gear pump liquid filling machine is equipped with accurate gear pump, which could...

DetailsTwo nozzles bottle filler

FG2100

When one tabletop liquid filling machine is not enough to meet market needs, we always suggest...

DetailsAdvanced Tabletop Gear Pump Liquid Filler

FG1050

The tabletop gear pump liquid filling machine is a versatile filling machine, and there is no need...

DetailsTabletop Overflow Filler

FL1100

Tabletop overflow filler is best suited for liquid with low to medium viscosity. The desired...

DetailsTabletop Piston Pump Liquid Filling Machine

FP1005

Tabletop piston liquid filler fp1005 is available for products like cleanser, dishwashing liquid,...

Details

Tabletop Peristaltic Pump Liquid Filling Machine - peristaltic pump liquid filler | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Tabletop Peristaltic Pump Liquid Filling Machine, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.