L-shaped angle and round bottle labeling machine

LTR3000

L-shaped angle and round bottle labeling machine

Round bottle labeling machine seems to be a simple machine, but it is not easy to carry out labeling in two different directions at the same time in actual production. Do you need a unique labeling machine that can apply labels in two different directions? This innovative labeling machine solves the need for both round bottle labeling and L-shaped angle labeling by combining two modes into one machine, allowing round bottles and jars to be labeled in two different directions at once, saving your time and money.

LTR3000 is a type of labeling machine that combine L-shaped and round bottle labeling. The process of attaching labels to the top and body of the bottle is that, when the bottle is placed on the conveyor belt, aligning through the guide rail, the top labeler and label folder will act through sensor sensing to apply label on top and fold the label to L-shape, through other guide rail, the product will then be convey to round bottle labeling unit that will label the body labels through wrapping the bottles. This made your product do not need to change labeling machine between top labeling and side labeling. Meanwhile, it is a high-precision labeling method that can achieve beauty and prevent tampering of the package in one step. It can satisfy products that need to be labeled on both the round body and the top, and is often used for pharmaceutical labels, dietary supplements and food packaging, such as health food, pharmaceuticals, jams, honey, meat sauce, seasoning sauce, nut jars, candy jars, etc.

L-shaped angle labeling and round bottle labeling machine saves your time and money

Another advantage of the L-shaped angle labeling and round bottle labeling machine is that it can accommodate varies round bottles, multiple product can use the same machine. This means that it takes up less space on the production line and provides more space for larger production areas. The two labeling modes, round bottle and L-shaped angle labeling is combined to label at once, increasing output and reducing the time required to change labeling equipment, at the same time, both mode can label separately if needed. L-shaped labels are often the best choice for pharmaceutical or medical and food industry’s round bottle, and are aesthetically pleasing and tamper-resistant. Tamper-resistant labels are not only used on food products, but can also meet pharmaceutical labeling requirements. For pharmaceutical companies, special tamper-resistant labels can provide a reliable seal to ensure quality and safety, and can also be used as security seal labels. The labels are made of highly specialized chemical materials and will resulting in an irreversible condition when torn off.

We not only manufacture standard labeling machines, but also provide fully customized and configured labeling machine systems to meet the needs of various products and facilities. From the design and system control of each project, to the creation of excellence and professional craftsmanship at all levels, each of our labeling machines can provide unique features to meet the special packaging needs of customers for different products and special label materials, we provide producers with advanced labeling systems to increase production output and ameliorate the labeling process.

Product Advantages

1. Meet the needs of health food and pharmaceutical products with high risk of tampering

2. Combines two labeling methods into one

3. Save time on multi-directional labeling of bottles and jars

4. Simultaneous labeling on the side and top

5. Round and L-shaped angle labels can be applied independently or simultaneously

Application & Advantage

Application products

The top and side of whole bottles and jars that required label. For example: pharmaceuticals, health food, jam jars, honey jars, sauce jars, nut jars, candy jars, biscuit jars, sealed products, tamper-proof products, and high precision electronic products.

Applicable container shapes

Round bottles, cylindrical products and products that require L-shape labeling.

Applicable Capacity materials

Glass, plastic, metal, paper.

Label types

Self-adhesive label, security label, void label, tamper evident label, film label, sealing label, hologram label, tamper evident label, holographic security label, non-residue security labels, qr code labels, laser anti-counterfeit label or transparent label (required transparent label electric eye).

Labeling method

Top of bottles with L-shaped 90-degree angle label folded, round and cylinder container surface with wrap around labeling, label around the bottle container with a full circle, 3/4 circle, 1/2 circle or part of the circle.

Industry

Pharmaceutical industry, food industry, biotechnology industry, beauty manufacturing industry, high precision product technology industry, etc.

- Features

1. Compliant with the pharmaceutical industry's labeling method for sealed bottles

2. Two types of labeling methods can be produced independently or in line production.

3. Good flexibility, labels can be applied to different sizes of bottles for a wide range of applications

4. Adjustable guide rail to guide the product to the labeling machine without adjust tools, simplify the production line

5. Speed encoder to control the speed of label and conveyor belt, so that the product labels are adhered to the same position

6. Comply with the pharmaceutical labeling requirements to ensure the security and safety of anti-tampering labels

7. Combine many special components to enable the labeling machine to apply labels on the bottle and the top simultaneously

8. Adopt the most advanced and user friendly microprocessor control and sensing system

9. L-shaped angle labeling + round bottle labeling machine, can apply two labels at one time

10. Synchronize Conveyor, labeling and folding unit speed

11. Can be integrated with the date coding system on the production line

12. Suitable for partial circumference, full circumference and overlapping round bottles labeling

13. When the labeling machine is connected with the production line, it will alert and stop labeling when its out of label.

14. Optional: When the visual inspection system checks the product for miss labeling and miss printing, it will reject the bottle out of production line

15. Optional: visual inspection system to check codes on products

16. L-shaped and C-shaped label through special folding equipment.

17. Flexible options for additional in and out feeding turntable or integration with other automated equipment

18. Can change the position of the guide rail according to the container size

19. Adjust the parameter setting according to the product labeling demand, easy to operate

20. The labeling applicator and convey guide rail are adjustable, which can apply to multi-size bottles and labels, and can be adjusted quickly without tools

21. Any user can easily replace labels in 3 minutes.

22. Suitable for variety of small amount production mode, reducing production line changeover and downtime

23. Special sealed labeling mode that meets the protocol and high precision of pharmaceutical and food industries

24. The labeling machine is designed according to the standard module, which can quickly customize and improve the performance of the machine.

25. The main structure of the machine is designed to be simple and durable, made of high quality stainless steel and hardened aluminum alloy.

26. High precision fiber optic sensor for high accuracy

27. Advanced stepper motor, stable operation and low noise.- Specification

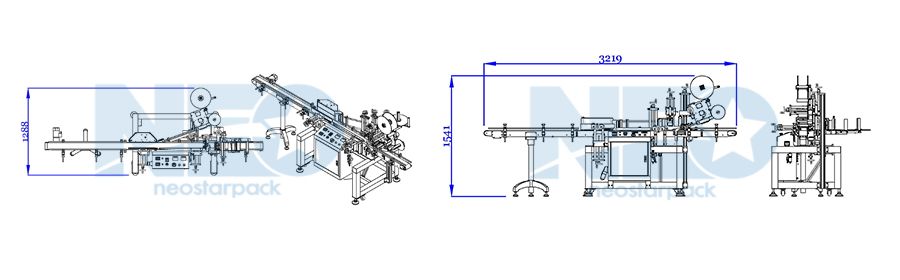

Specification Automatic level Full-automatic motor Step motor or option servo motor Labeling speed 20 ~ 60pcs/per min (depending on label and product size) Labeling accuracy +/-1mm Label size (W) 10-100mm (L) 20-250mm Label roll (ID) 75mm (OD) 280mm Product size (W) 10-100mm (L) 20-250mm Power requirement 110 or 220VAC, 50/60Hz, single phase Machine dimension (L) 3219mm (W) 1288mm (H) 1541mm * Dimensions may vary depending on configuration, detailed specifications are subject to actual product.

- Option Accessories

- Date coder

- Automated Optical Inspection

- Production line product rejection system

- Transparent label sensor

- Bottle spacer module to ensure equal distance product

- Advanced Motion Controls: Servo Drives and Controls

- HMI human-machine interface

- Customized special machine size for production space

- Machine frame can be upgraded to having case body

- Infeed turntable and outfeed turntable

- Machine safety cover

- Introduce Movies

- Related Products

Tabletop Wrap Around and Top Labeler

LR1300 / LT1100

Equipped with a round bottle labeling head and a top labeling head, wrap around and top labeling...

DetailsExquisite Cabinet Free Set Round Bottle Labeler

LR2100

Free set round bottle labeler LR2100 can be widely used in labeling cosmetics, food, beverage...

DetailsWrapping Around Labeler

LR2300

Wrapping around labeling machine LR2300 compact design with high mobility for labeling round...

DetailsAutomatic Round Bottle Labeler

LR3000

Automatic round bottle labeler LR3000 is suitable for food, pharmaceuticals, beverage, and cosmetic...

DetailsAutomatic Round Bottle Labeling Machine

LR4000

Automatic round bottles labeling machine LR4000 is available for any kind of erective plastic...

Details

L-shaped angle and round bottle labeling machine - L-shaped angle and round bottle labeling machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include L-shaped angle and round bottle labeling machine, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.