Top Label Applicator

LA1100

automatic top label applicator,label applicator

Top label applicator is a labeling device that using stepper motor to achieve high-precision positioning through signal control. It accurately affixes labels to products or packaging, making it suitable for industries that require precise label application, such as the food, beverage, pharmaceutical, cosmetic, and other packaging industries. The key point of accurate label positioning is the label applicator with stepper motor.

The stepper motor label applicator LA1100 can automatically peel off the label and accurately paste it to flat products of various sizes, providing a neat product labeling, enhancing the brand image and achieving marketing results. Whether for standalone labeling needs or integration into existing packaging lines, LA1100 can offer a fast and economical labeling solution. It saves production time, space, and costs, and improving labeling production efficiency.

Exquisite Label Applicator LA1100 - suitable for various labeling

The LA1100 is a larger-sized label applicator. The biggest difference between LA1000 and LA1100 is the machine size. LA1100 is bigger to provide more stable and efficient labeling, as well suits for more labeling requirements. Some components of the LA1100 are specifically arranged in different colors to make it more colorful, it also using lighter materials for easier transportation and installation.

The labeling path of the LA1100 is short, making it convenient to replace label rolls, and easier to adjust the labeling angles. With a simple and lightweight structure, it can be installed on a packaging machine without impacting on the existing equipment. It is more suitable for high-accuracy labeling requirements of technology industry electronic products, food, pharmaceuticals, chemicals, precision electronic components, packaging bags, SSDs, RFIDs, etc.

Efficient labeling solutions for a variety of packaging machines

The labeling speed of the LA1100 reaches 10 meters per minute. It is capable of standalone labeling operations and can also be integrated into a production line, providing flexibility for changeover.

By install an extra swing buffer roller onto LA1100 can increases the label dispensing length, accelerates the labeling speed, allowing you to meet higher production needs and produce more products in less time. It is a fast and economical label applicator that is available to connect with your existing packaging line, making your products more attractive and competitive.

If you are interested in our LA1100, please fill out the form below with detailed information. We will contact you as soon as possible.

Advantages:

1. The label applicator is compact, easy to install, and space-saving.

It’s suitable for various place to use, saving cost and time.

2. With a short labeling path, quick and simple label roll replacement to enhance production efficiency and accuracy.

3. The labeling angle allows to be adjusted flexibly, which is appropriate for various product shapes to meet diverse requirements.

4. It’s driven by a stepper motor, ensuring precise and stable labeling, and reducing labeling errors.

5. Intelligent microcomputer controls the machine, making operation easy. It can be connected to other automated devices, enabling production integration and resource-saving in manpower.

Application & Advantage

Applications

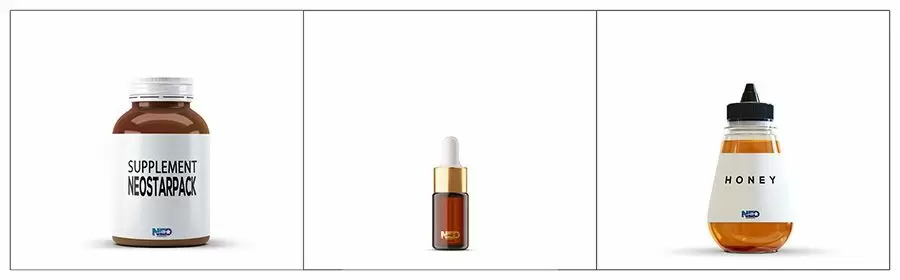

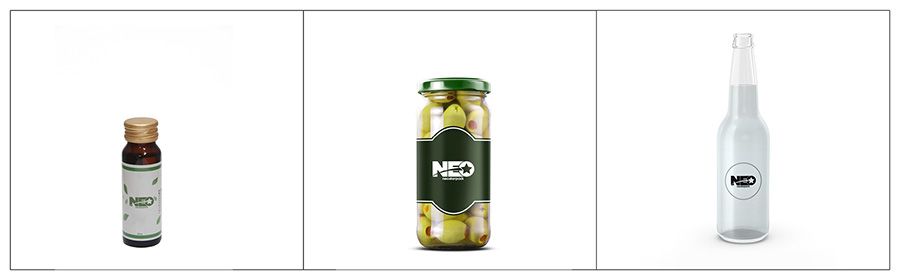

Food & Beverage: Juice, canned food, condiments, boxed ice cream, bagged food, food storage container, etc.

Pharmaceutical and supplements: Various bottle, infusion, medicine box, dietary supplements, etc., including product name, dosage, and expiration date.

Personal care and cleaning supplies: Conditioner, Shampoo, Body soap, Lotion, Sunscreen, Detergent, Laundry Detergent, Dishwashing, etc.

Industrial electronic products: Electronic Component, Color Box, Hardware Part, Terminal, SD Card, DDR, Battery, Engine Oil, Coolant

Logistics products: Carton, Shipping Mark, Barcode, Promotional Label

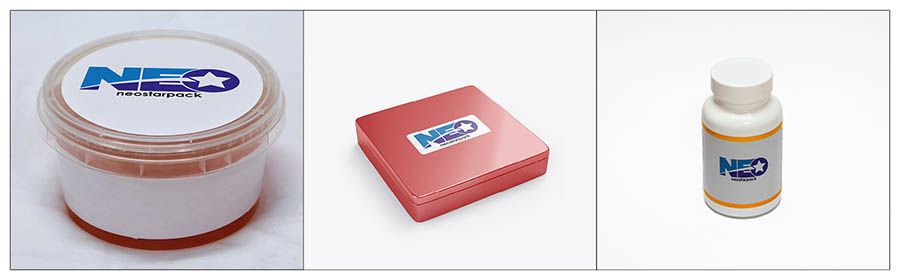

Suitable product shape

Three-dimensional products, such as square boxes, flat bottles, round bottles, etc.

Flat products, such as cartons, paper bags, packaging bags and paper bags

Suitable Materials

Paper, Glass, Aluminum Foil, Plastic (PVC, OPP, PP, PE, PET, HDPE, PLA), Metal (tinplate, aluminum cans, stainless steel), Styrofoam

Suitable Labels

Self-adhesive labels, Promotional labels, Anti-counterfeit Labels, Ingredient Labels, Laser Labels, Double-layer stickers, Bookmark Labels, Barcode Labels, PC Nameplate Stickers, Fragile Stickers, Heat-resistant Stickers, Polyester stickers, Serial Number, Product Labels, Heat-sensitive labels, Frozen Stickers, Void Label

Labeling style

Driving label applicator by a stepper motor. When the paper roll reaches peel plate, peel off the sticker and paste it onto products. And the back paper will be rolled to back paper spool disc automatically.

Suitable industries

Food Manufacturing (processing) Industry, Baking Industry, Pharmaceutical Industry, Chemical Industry, Daily Chemical Industry, Technology Industry, Biotechnology Industry, Manufacturing Industry, Cosmetic Industry

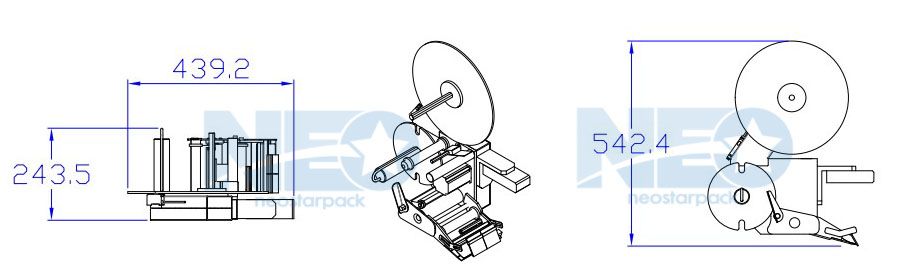

Machine layout

- Features

1. Driven by stepper motor; ensures stable and accurate labeling.

2. The structure of label applicator is simple, which is suitable for setting up on various production lines; space-saving.

3. Intelligent sensor detection system, accurate labeling without missing.

4. The label applicator is equipped with a back paper spool disk, which is convenient to remove the used back paper, saving time and manpower.

5. Translucent spool disc design for quick checking residual stickers.

6. Intelligent Microcomputer Control, easy to learn the operation, one-button setup.

7. Multiple memory modules: available to switch between different production lines and improve efficiency.

8. Stepper motor drives the device, providing high labeling accuracy.

9. The label applicator makes it easier to adjust the height, angle and position of the conveyor and bracket according to production needs.

10. Provide a flexible label applicator design to meet different labeling needs.

11. It can be integrated with the PLC control system to connect production lines, improving the automation level, and reduce labor costs.

12. Setting the parameters through precision label sensor, accurately detecting labels and back paper to avoid errors.

13. Automatic amplifier detection: Accurately control the label length to reduce waste.

14. Adjustable labeling speed: Labeling speed can match the production line speed to avoid delays.

15. The conveyor speed is synchronized with the labeling speed to make sure the smoothness and consistency of the labeling.

16. Intelligent Sensor Detection System: Automatically detects the product position. If there is no product, the machine won't dispense labels.

17. Precise stepper motor driving LA1100; to smoothly and quickly complete labeling tasks and increase productivity.

18. Industrial grade standard switch is durable with long service life.

19. Automatic counting function, clearly display the labeling output, easy to take control of the production line status.

20. Advanced Test Mode actively detects the status of electronic components and take control of the operation.

21. Versatility: You can choose various packaging equipment as an option, such as verification system and top pressing unit.

22. Customized production: Install a printer bracket according to requirements, effectively utilizing production space.

23. Round bottle wrapping unit or spindle wrapping unit can be chosen to meet different labeling requirements.- Specification

Labeling Motor

Stepper Motor

Labeling Speed

12 m/min (depending on product and label size)

Labeling Accuracy

± 1mm

Label Size

Width: 10-150mm, Length: 10-250mm

Label Roll

Inner Diameter 75mm, Outer Diameter 300mm

Power Supply

110 or 220VAC, 50/60Hz, single phase

Machine size

(L) 529mm (W) 570 mm (H)805mm

※ Actual product specifications may vary

- Option Accessories

- Japanese Clear Label Sensor

- High-grade servo motor, labeling speed reaches 40m/min

- Date Coder, Laser Printer

- Smoothing Unit (brush, sponge roller)

- Advanced Electric Lifting Mechanism

- PLC System

- Automatic Label Detection System

- Automatic Optical Inspection

- Customized module for different label size.

- Round Bottle Wrapping Unit, Spindle Wrapping Unit

- Introduce Movies

- Related Products

Label Applicator

LA1000

A label applicator plays an important role in a labeling machine, it is the heart of a labeler....

DetailsTabletop Automatic Top Labeler

LT1000

The Tabletop automatic top labeler LT1000 is an economic, budget friendly piece of machinery...

DetailsTabletop Top Labeler

LT1100

Our LT1100, tabletop top labeler works with high efficiency, while provides perfect labeling...

DetailsTabletop Two-Sided Labeler (with two label applicator)

LT1252

Tabletop two-sided labeler LT1252 is designed specifically to fulfill labeling tasks with high...

DetailsAutomatic Top Labeler with Stand

LA2000

The labeler is a self-adhesive label labeling machine with flexible and diverse applications....

Details

Top Label Applicator - automatic top label applicator,label applicator | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Top Label Applicator, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.