Automatic Front and Back Labeler

LD3000

Two-side Labeler,double-sided labeler

Automatic Front and Back Labeler LD3000 is a machine that can attach labels on both sides of the product or container at the same time, affixing the stickers on the front and back side respectively, and reducing the process of repeated feeding or stopping the general single-sided labeling machine. LD3000 is suitable for bottles of various sizes and different materials, such as plastic bottles, glass bottles, PET bottles, metal bottles, etc. It can also be applied to containers with flat surfaces such as square bottles and paper boxes, covering a wide range of product types. With two high-performance label applicators, ensuring high productivity during continuous production work.

High accuracy and flexibility of the double-sided labeler help you reduce the cost and error rate

The advantage of double-sided labeler LD3000 is that it can improve production efficiency, accuracy and flexibility, then reduce labor costs and error rates. In addition, the position and angle of the label applicator can be adjusted easily to meet different product needs. The labeler accurately detects the position and direction of the product with advanced sensors, synchronize the labeling speed by a stepper motor or servo motor. Plus, an overhead conveyor to press the product, it can stabilize the container, achieving high-quality labeling without missing a label. At last, ensuring stickers attached on the product firmly with sponge rollers and brushes.

Dual use! LD3000 easily achieves the needs of single and double labeling

According to the product characteristics, you can use the labeler as a front & back or simply side labeling machine. Both label applicators can be switched on and off freely, providing choices of single or double-sided labeling mode:

•If you only need one side label on the product, you can choose the single-sided (the front or back) labeling mode to complete the labeling work.

•If you need to paste two labels on both sides of the container, you can choose double-sided labeling mode, using two label applicators at the same time to complete the labeling work.

Different double-sided labeling machine may have different labeling modes. Neostarpack will analyze your product characteristics and specifications to provide professional advices and help you choose the right labeling machine. For customers with varied production needs, we can give flexible customization, retain the design of brackets and holes to facilitate the increase of options in the future, and combine other machines, such as packaging machines, hot stamping machines, collecting machines, filling machines, and capping machines, to create automated packaging lines.

Advantages:

- Improve efficiency

Labeling on the front and back of product at the same time. Compared with the labeler that separately labeling on two sides, LD3000 reduce the labeling time. - Reduce labor cost

Its automated processes require the least manual operation. - Shorten the downtime

Due to labels are applied to both sides of the container at the same time, the downtime associated with label roll replacement or mechanism adjustment will become less. - Improve product appearance

Beautiful labels enhance the visual appeal of the product and ensure that the labels on the product are neat, making the packaging look more professional. - Precise calibration

Make sure the position will be prefect! Calibration units make your product always attach to the correct designated position.

Application & Advantage

Suitable Goods:

Food & Beverages: The nutrition facts and brand of food shortage jar, juice, water, energy drink, hard drink, mayonnaise, jam, ketchup, mustard, maple syrup, pastry, snacks, and prepackaged food.

Personal care products: The container needs to be labeled ingredient list, instruction, brand like shampoo, conditioner, lotion, essential oil, hair dye, hair treatment, and skin care product.

Pharmaceuticals and healthcare products: Medicine bottle, Prescription drug, Supplements, Fish oil, and Vitamins.

Cleaning supplies: The instructions and safety information of air fresheners, pesticides, floor cleaners, laundry detergent, bleach.

Pet care products: Pet food container, grooming product, pet drugs.

Industry and chemicals: Label shows product information and warning sign of machine parts, car cleaners, lubricants, and engine oils.

Electronic product: Show specifications, functions and brand of gadgets such as phones, laptops, boxed accessories, electronic products, paper cartons, etc.

Suitable Product Shape:

Square Bottle, Cubic Container(paper box, metal box, plastic box, glass bottle), flat bottle.

Suitable Product Material:

Paper, glass, aluminum foil, plastic (PVC、OPP、PP、PE、PET), metals (tinplate, aluminum, stainless steel)

Suitable Labels:

Fragile stickers, transparent labels, Ingredient facts, promotion labels, waterproof stickers, anti-counterfeiting labels, self-adhesive labels, nutrition facts, batch code, safety warning, void sticker.

Labeling Style:

the product pass through 2 label applicators, detecting by sensor, and attaching stickers on it with side-labeling, meanwhile, smoothing labels by sponge roller and brush to avoid wrinkles and bubbles.

Suitable Industries:

Food & Beverage Industry, Pharmaceutical industry, Biotechnology industry, Technology industry, Manufacturing Industry, Cosmetic Industry, Chemical Industry

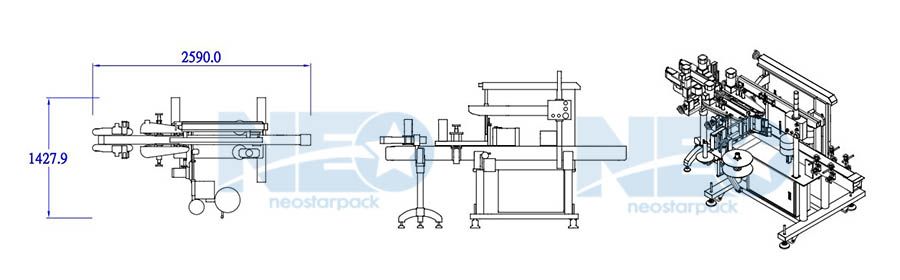

Machine Layout:

- Features

1. Intelligent Binary Decode allows to synchronize the label applicator, conveyor and top-pressing unit after the adjustment, save time on product change.

2. High Adaptability: You can adjust the labeler to fit product size, various bottle and container packaging.

3. It can connect with your existing production line, in turn to blend in packaging production and manufacturing process.

4. User-friendly Interface: The operator can easily arrange and control labeling process.

5. Colored HMI Screen: It’s simple to set and modify parameters, labeling position and labeling module.

6. Labeling preparation is flexible, fast and easy, and completing precise front & back labeling.

7. It’s equipped with 2 high performance label applicators, allowing continuous production and ensure high productivity.

8. Automatic front and back Labeling machine is shipped with calibration function, providing better labeling results.

9. Both label applicators of LD3000 can be adjusted according to different product features and designs.

10. You can fine-tune labeling height and angle in the light of container size. Its biggest adjustable angle is 20 degrees.

11. You can choose to add a wraparound device. Thus, the labeler can attach 1/2 or full circle label onto round bottle.

12. You can choose bottle spacing unit to meet high production capacity needs.

13. Labeling result is refined with wrapping unit. (Square bottle needs special mechanism.)

14. Optional PLC control system and intuitive operation interface provide easy operate while converting production line. You don’t need to adjust sensor setting, saving time.

15. Detect missing label function: maintain the quality of finished products.

16. Stepper motor control stable label dispensing

17. Japanese sensor precisely detects labeling position.

18. The conveyor belt meets cGMP standards, and its coefficient of friction (COF) is low, which can delivery product steadily.

19. The labeler made of SUS# 304 stainless steel and aluminum alloy, which is firm and durable

20. LD3000 can connect with packaging machine, filler, capper, and capsule counter to upgrade an automated production line.

21. Programmable Logic Controller(PLC) precisely take control of labeling works.

22. Hand wheel with number position indicator allows you to adjust to the best arrangement.

23. Dual label applicator adopts synchronization labeling mode, and single labeling mode is available too.

24. The machine frame of LD3000 is stainless steel base, helping labeling work remain stable and excellent.- Specification

- Automatic level: Automated machine

- Labeling Motor: Stepper Motor

- Labeling Speed: 20~40 pcs/min (according to product and label size)

- Label Size: (Length) 20-300 mm, (Width) 10-100 mm

- Product Size: Diameter 20mm-125mm, Height 30-160 mm

- Label Roll: Inner Diameter 75 mm, Outer Diameter 300 mm

- Accuracy: ± 1 mm

- Power Supply: 110 or 220 VAC, 50/60 Hz

- ※ Actual product specifications may vary

- Option Accessories

- Servo Motor

- Angled Module

- PLC Control System

- Transparent Label Sensor

- Infeed or Outfeed Turntable

- Smoothing Unit e.g., Brushes, Sponge Rollers

- Infeed or Outfeed Platform: driven by motor

- Hot Stamp Printing Machine, Laser Printer, QR Code Printer

- Pneumatic Round Labeling Module

- Introduce Movies

- Related Products

High Speed Front and Back Labeler

LD4000

High-Speed Front and Back Labeler LD4000 is designed to increase production efficiency and accuracy,...

DetailsAutomatic Three-sided Labeling Machine

LD3053

3-sided labeling is a common type of packaging for square bottles, which is widely used in food,...

DetailsAutomatic Square Bottle Labeling Machine (Three-sided & Top Labeling)

LD3055

Neostarpack LD3055 Automatic Three-sided Labeler with top labeling function provide a comprehensive...

DetailsTop and Bottom Tamp Labeling Machine

LS3100

Top and bottom tamp labeler machine is specifically designed for special containers and is used...

DetailsAutomated Chemical Products Filling Capping and Labeling Packaging Line

FP5150 / CC4000 / LR3000

In usual, it’s necessary to consider the chemical property of the product itself when manufacturing...

DetailsEdible oil Filling Packaging machine

Edible oil is around our world. Most of the common edible oils are vegetable oils and in liquid...

DetailsBottle Capsule Counting Machine Line

TM4100 / CW4000 / LR3000 / RT1000

Capsule counting complete line for healthy food is usually for the pharmaceutical factory and healthy...

Details

Automatic Front and Back Labeler - Two-side Labeler,double-sided labeler | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Automatic Front and Back Labeler, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.