Bottle Unscrambler

BU5500

Bottle unscrambler

The bottle unscrambler BU5500 is easy to operate, understand and maintain. When using, operator only need to put the bottle container into the empty bottle storage tank. Bottle elevator will then feed the bottle to the bottle unscrambler. The bottle unscrambler system will automatically organize all bottle into order with orderliness orientation.

Meanwhile, distribute track will arrange bottles neatly on conveyor. When conveying, the bottle stays standing and moves forward in one direction, and the bottle will be sent to the next production process, such as filling machine, labeling machine, counting filling and packaging machine, etc., which can greatly increase the production line efficiency to meets the needs of fully automatic production line.

Bottle unscrambler meets the stability and safety requirements of automatic filling lines

The high-speed bottle unscrambler BU5500 can completely replace manpower to arrange empty bottles on the conveyor. It has a high-capacity bottle feeding and unscramble function, which can accomplish the automatic feeding of empty bottles and increase the overall efficiency. The BU5500 is a linear multi-track design and is unscramble at a speed of up to 100 bottles per minute. No matter what size and shape of the bottle (round bottle, square bottle, oval or special bottle shape), high speed or low speed production, pharmaceuticals, nutrition supplement, food, cosmetics or chemicals, etc., are all suitable for using automatic bottle unscramblers to help you maximize the efficiency of your production line. BU5500 has a built-in storage tank and a bottle unscrambler rotating turntable, which not only saves a lot of space, but also can be combined with other packaging equipment into production line. The system and functions of the machine meet the specifications of the pharmaceutical industry. In addition to the pharmaceutical industry, it can also be used in the food and beverage industry and cosmetics industries. The bottle unscrambler system integrates multiple functions and can integrate with all kind of packaging production lines to provide excellent solutions for you.

Product Advantages

1. Flexible, fast conversion and low maintenance rate

2. There are multiple distributing tracks to unscramble bottles efficiently

3. Large capacity bottle storage tank

4. Changing production bottles is quick do not need tools

5. Save space, and can easily connect with existing equipment

6. Ergonomic design, easy to operate, understand and maintain

Application & Advantage

Suitable for

Detergent, Syrups, laundry detergent, dishwashing detergent, baby oil, shower gel, shampoo, hand soap, lotion, lotion, drinking water, beverage, juice, sauce, soy sauce, etc.

Suitable Industries

Pharmaceutical industry, biotechnology industry, food and beverage manufacturing, chemical manufacturing, cosmetics manufacturing.

Applicable bottle

Plastic bottles, round or oval bottles, and other special bottles.

- Features

1. Applicable to all kinds of bottle containers

2. With multiple speed modes, you can choose low speed or high speed

3. The production speed is up to 100 bottles per minute, which meets the general bottle specifications.

4. There are multiple distributing tracks for conveying and unscramble bottles quickly

5. Each bottle unscrambler is customized for you to meet your bottle sizes. When changing different bottle sizes products, you can easily convert by replacing parts

6. It can accurately turn over and organize bottles

7. PLC industrial control system

8. Bottle jam detection system, when the bottle container is full on the conveyor belt, it will automatically pause the bottle feeding.

9. Out of bottle detection system, it will stop automatically when the amount of bottles in the storage tank is insufficient

10. Abnormal detection alarm system to prevent improper operation

11. No need to manually arrange empty bottles on the production line

12. The touch screen can switch between two languages for conveniently operation of the machine

13. Flexible, fast conversion and low maintenance rate

14. Photoelectric sensor and optimized units for smooth operation

15. Provide parameter memory function, which can save and load multiple sets of recipes for changing products

16. The sensor of the outfeed bottle jamming to detects the smoothness of the bottle conveying.

17. Machine frames and outward are made of 304 stainless steel and high standard aluminum alloy for aesthetic and durable

18. Bottle positioning unit

19. The speed of the unscrambler can be adjusted according to the capacity of the subsequent production line machines

20. The bottle unscrambler can operate independently, and can also be connected to the existing automatic filling and packaging line to increase the overall production capacity.

21. In addition, it can be expanded to integrate the air rinsing machine.

22. Advanced design simplifies maintenance procedures

23. Quickly and regularly place the bottles firmly on the conveyor belt for the subsequent production line machines

24. High performance and space saving, very suitable for pharmaceutical and nutrition supplement product and food processing manufacturers.

25. Customizable mechanism to provide the pharmaceutical industry in compliance with CGMP standards- Specification

- Automation level:Full-automatic

- Speed:Max:120bottles/per min

- Applicable bottle:HDPE, PET, LDPE

- Applicable bottle style:Bottle height:100mm~300mm; can be customized

- Power supply:110 or 220VAC, 50/60Hz, single phase

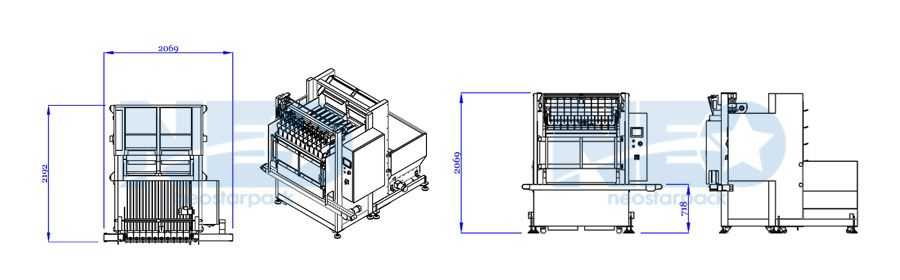

- Machine Dimensions:(L)2500(W)2500(H)2200mm

- *Actual product specifications may vary

- Option Accessories

- Static elimination device for bottle unscrambler storage tank

- Bottle air rinsing machine

- Liquid level surface hopper sensor

- Sensor to bring tipped over bottles back to the storage tank.

- High-level human-machine-interface functions: output report, multi-level authority system, production history record

- The conveyor belt can be lengthened: the length may vary depending on the option selected

- Introduce Movies

- Related Products

Automatic Bottle Feeding Machine

NRT-100

Automatic bottle feeding machine used in Pet bottles and glass bottles.

Details

Bottle Unscrambler - Bottle unscrambler | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Bottle Unscrambler, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.