Semi-Automatic aluminum Screw Capping machine (ROPP Capper)

CR1000

ROPP capping sealing machine

Semi-Automatic Aluminum Screw Capping Machine CR1000 is suitable for products sealed with spiral aluminum cap products, such as wine bottles, olive oil, edible oil, seasoning, functional health drinks, high strength distilled alcohols such as vodka, whiskey, rum, sorghum, and liquid pharmaceuticals. Aluminum Capping machine is commonly referred to as ROPP capping machine, also known as Anti-theft Aluminum Cap Capping Machine. The aluminum cap capping is the ideal packaging form to prevent any product from being broken and open.

The ROPP Capping Machine's capping head can also be used to seal aluminum screw caps on standard plastic bottles. Semi-Automatic Aluminum Cap Capping Machine is easy to operate. Put the lid on the container, place the bottle on the capping machine platform, press the button. The capping machine platform will automatically rise to screw the cap to the container bottle. The whole capping process only takes a few seconds to screw the cap with high and stable torque, efficiently achieving the precision capping seal.

Precise Wire-Cut Capping System, Good Sealing Quality.

Semi-Automatic Aluminum ROPP Capping Machine adopts a precise wire-cut capping system, equipped with four roller capping chucks. It adopts an electric rotary capping head for structure sealing, which provides continuous and stable torque to ensure the sealing of cap and bottle mouth to complete the perfect aluminum cap screw sealing operation and achieve high precision capping quality. The tightness of the cap can be adjusted and changed to suit different containers and caps sizes and adjusted the height of the cap according to the container height.

Bottle Positioning Device Enhances Capping Quality and Accuracy.

Semi-Automatic Aluminum Cap Capping Machine is equipped with a positioning device to avoid distorted bottles, jammed bottles, inaccurate positioning, and other adverse effects to improve capping quality and accuracy. The machine is easy to operate, quick to learn, and easily switched on or off according to the operation mode. One operator can carry out production to achieve better productivity and standardization.

Each capping head can only seal one size of caps, and if you want to seal different cap sizes, you don't need to buy a new capping machine. You can easily replace the optional capping heads for various operations to significantly improve the machine's production efficiency. The CR1000 is the best packaging machine for small and medium-sized production to achieve the best functionality of aluminum cap capping.

Product Advantages:

- Suitable for all kinds of long and short aluminum caps or aluminum alloy caps.

- One capping machine can achieve the best aluminum capping and packaging.

- Low noise, low power dissipation.

- Easy to use, high durability, improve work efficiency, and reduce cost.

- High precision capping, anti-theft, avoid liquid leakage.

Application & Advantage

Applicable Caps

Screw caps, ROPP caps, Aluminum Pilfer Proof caps, short aluminum caps, Stelvin screw caps, Aluminum Screw Cap for BVS Bottle, Aluminum Pre-threaded Screw Cap, etc. are all suitable.

Applications

Alcoholic beverages, functional beverages, dairy products, sesame oil, olive oil, red wines, seasonings, small volume beverages, sample wines, spirits, concentrated fruit juices, syrups, enzyme beverages, vitamin drinks, health foods, chemicals, liquid pharmaceutical medicines such as cold syrup, oral liquids, disinfectant alcohol, cosmetics, toiletries, lubricants, etc.

Application Industry

Pharmaceutical industry, chemical industry, health food, food and beverage industry, biotechnology industry, daily necessities industry, etc.

ROPP Cap Size Range

18 to 32 mm

Capping Method

Crimping

- Features

-

1. Suitable for anti-theft products that ensure the original seal of products.

2. Suitable for aluminum ROPP bottle caps.

3. Sealing up to 15 containers per minute.

4. Prevents leakage of pharmaceuticals, beverages, and food products, easy to operate and increase efficiency.

5. Allows capping head to be changed on the same capping machine for different cap sizes.

6. Simple height adjustment, easy and fast setting.

7. High-torque rotating cap, easy to finish the bottle sealing.

8. Bottle Mouth Positioning Device provides high capping quality and precision.

9. The machine can easily switch on or off to ensure staff production with simple operation.

10. Equipped with emergency stop button device to provide operator safety protection.

11. Integrated structure of aluminum cap sealing machine and aluminum cap press, easy maintenance and convenience.

12. Applied to different container diameters without replacing parts.

13. The machine size of CR1000 is equivalent to a desktop water dispenser, not limited by space, suitable for enterprises with small and medium-sized production space.

14. Applicable to a wide range of products, convenient for diversified production.

15. The capping tightness and capping speed can adjusted according to product requirements.

16. Customized capping head is optional for replacing corresponding parts to produce various sizes of products with one capping machine.

17. Made of high-grade SUS304 stainless steel and high specification hardened aluminum alloy, stable and durable.

18. The capping machine is made in Taiwan from design to manufacture, with excellent quality and perfect service.

19. We provide complete after-sales service and training.

20. Compact structure and sleek body of the capping machine can be widely used in industries.

21. Acrylic protective cover to ensure the safety of the operator.

22. Meet different country specifications and provide suitable power demand configuration. - Specification

-

- Automation Level: Semi-automatic

- Capping Head: 1 pc

- Capping Speed: 5~15 bottles/min (varies according to user operation)

- (ROPP)Aluminum Cap Specification: 18 to 32 mm

- Power Requirement: 110/220VAC,50/60Hz

- Machine Weight: 90KG

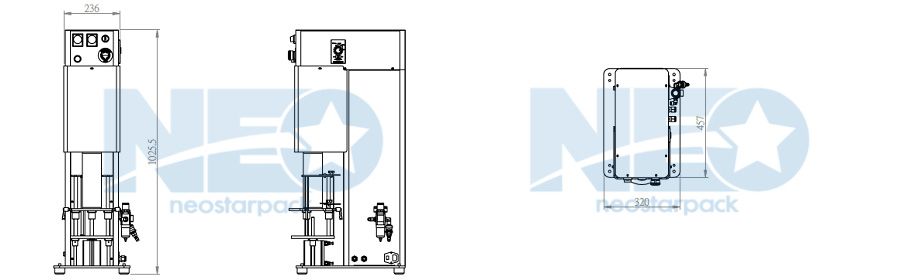

- Machine Size: 320x457x1026mm

- *Dimensions may vary depending on bottle and cap size; detailed specifications are subject to actual shipment.

- Option Accessories

-

- Mobile cart

- Customized capping head

- You need to have an air compressor.

- Foot-operated control switch

- Introduce Movies

- Related Products

-

Automatic Aluminum ROPP Capping Machine

CR4000

The automatic aluminum ROPP capping machine uses the automatic aluminum cap feeding and capping...

DetailsAutomatic Overflow Filling & ROPP Cap Capping Production Line

NFL-465+NCA-410

Automatic Overflow Filling & ROPP Cap Capping Production Line is widely applied in food, beverage,...

DetailsAutomatic Capper

CC4170

Automatic Capper CC4170 can be easily adjusted with the capping head to meet different capping...

DetailsAutomatic Indexing Spindle Capping Machine

CS3000

Automatic indexing spindle capping machine uses the universal gripper to cap with proper torque,...

DetailsAutomatic Dual Servo Motor Capper

NCW-415S

NCW-415S Automatic Dual Servo Motor Capper can be easily adjusted with the capping head to meet...

DetailsAutomatic Counting Capping And Labeling Line

NTM-420+NCA-410+NLT-210

Automatic Counting Capping And Labeling Line is design for packaging regular counting materials,...

Details

Semi-Automatic aluminum Screw Capping machine (ROPP Capper) - ROPP capping sealing machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Semi-Automatic aluminum Screw Capping machine (ROPP Capper), labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.