Automatic Top Labeler

LT4000

Flat Surface Labeling Machine

The automatic top labeler LT4000 can continuously and accurately label a large number of labels. It is suitable for all kinds of flat-surfaced, side or top of products, such as boxes, cartons, plastic bags, aluminum foil bags, paper bags, medicines, cosmetics, skin care products, egg boxes, food, Agricultural products, gift boxes, circuit boards, memory card, industrial batteries, wet tissues, contact lens cases, etc.

Top labeller LT4000 has the advantages of high productivity and low manpower requirements. Depending on the size of the product and the label, it can label 40 to 80 pcs per minute. The high-performance stepping motor achieves precise positioning and labeling in a short time, and the signal conveys the precise angle and speed. The programmable controller executes the labeler's full automation and digital logic to achieve the synchronous operation performance of the mechanism, and uses a microcontroller to achieve high stability and high precision.

The automatic flat top labeling machine LT4000 displays the production output on the digital panel in real time, which is convenient for tracking the production capacity. Its Simple parameter adjustment makes obscure parameters no longer an obstacle. The labeling machine can be adjusted according to the needs of different products to achieve the best labeling effect.In addition, for special needs, a single product can be set to continuously attach multiple labels, such as a series of contact lenses, which can be accurately pasted on the packaging of each contact lens.

The label is an economical and affordable way to display the product information beautifully. The automatic top labeler LT4000 can greatly increase the labeling production capacity. Any product that uses self-adhesive labels can be applied to the top labeling machine LT4000 to achieve a neat and consistent product label. It can meet the needs of various industries and improve the competitiveness of your products.

High-Speed Automatic Top Labeler Meets Automatic Packaging Production

The automatic top labeling machine is operated through the HMI touch screen, and the labeling parameters can be set by touch, which speeds up the changing of the labeling product line. The labeling position can be finely adjusted by the hand wheel without any tools, which improves the efficiency of product line changing. The design also simplifies cleaning and operation. The operator does not need to have a professional technical background, and it can be easily used. Label replacement can be completed within 3 minutes, reducing production downtime.

The top labeler LT4000 can apply various flat, side and top labels, and quickly provide a diversified capacity plan for labeling of various industries. Self-adhesive labels, promotional labels and anti-theft labels are all applicable. The labeler can operate independently, or integrate other packaging machines to become an automatic labeling and packaging production line. In addition, a variety of options are provided to improve the efficiency of the labeling machine, such as: clear label sensor, date printer, customized conveyor belt, pneumatic spacer gate, etc. LT4000 is suitable for medium and large automatic packaging production lines with speed of more than 50 pcs per minute and needs fast and accurate labeling. The machine can be customized to create a unique automatic labeler.

Advantages:

1. High applicability,It can be flexibly used with various packaging machines.

2. Smart automatic mode, production immediately after booting.

3. Multiple labels can be attached to a single product.

4. Automatic calculation of total output to manage production schedule.

Application & Advantage

Suitable for

flat-surfaced, top, and side of products, such as: paper boxes, gift boxes, cartons, plastic boxes, tin boxes, aluminum foil bags, folders, paper bags, tags, cosmetics, electronic products, batteries, egg boxes, top of bottles and cans, contact lenses.

Suitable Labels

Self-adhesive sticker labels, anti-counterfeit labels, promotional labels, tamper-evident labels, Description label, pop-up labels.

Labeling style

Labeling on flat-surface, top or side.

Suitable industries

Pharmaceutical, biotechnology, technology, cosmetics, food and beverage, chemical, hardware, groceries, daily necessities, logistics, etc.

- Features

1. Controlled by a microcomputer, providing excellent stability for long-term production.

2. The sponge roller has better compliance with thick labels.

3. Stepping or servo motors can be selected according to requirements.

4. Touch screen to enter parameters, easy to operate.

5. The labeler can be partially customized according to the special product.

6. Can be changed to brush for thin and light products.

7. Low friction conveyor belt product conveys smoothly without damage.

8. Manually and quickly fine-tune the labeling height and angle.

9. Advanced Japanese sensor detection system makes precise labeling.

10. intelligent detection and automatic stop: label break, lack of label or label run out.

11. The conveyor belt and labeling speed can be adjusted synchronously.

12. Customizable extra-large conveyor belt for special needs.

13. Automated model with smart mode, production immediately after booting.

14. Decoder for keeping track of output and Maintain a constant rate of production.

15. The applicable product range is wide, and the operation of changing the production line is simple.

16. From design to manufacturing, it is made in Taiwan, with perfect quality and service.

17. High applicability,It can be flexibly used with various packaging machines.

18. Optional: clear label sensor,which is suitable for both transparent label and general label.

19. Strong and durable, made of stainless steel SUS#304 and hardened aluminum alloy.

20. Delayed labeling can be set to fine-tune the labeling position.

21. Equipped with an emergency stop button to control the production line at any time.

22. Optional: HMI, can save multiple production memory.- Specification

- Labeling speed: 40~80 pcs/ min (depends on products and labels size)

- Label size: (W) 10~100 mm / (L) 20~250mm

- Label reel: Inner diameter 75mm / Outer Diameter 300mm

- Accuracy: ± 1mm

- Supply power: 110V or 220VAC, 50/60Hz

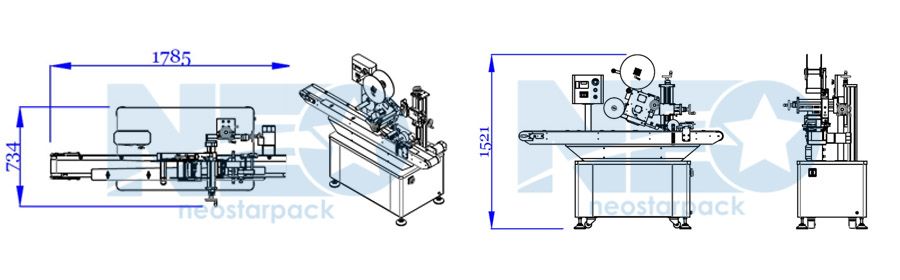

- Machine size: (L) 1459mm (W)796mm (H)1400mm

- Option Accessories

- Photoelectronic sensor for transparent labels

- Powerless top hold-down belt (suitable for applications that are light and thin)

- Date coding machine

- Servo Motor

- Capper

- Filler

- Tablet counter

- Introduce Movies

- Related Products

Automatic Top Labeler for Sd Cards

LT210SD

Top labeler for SD cards LT210SD is built for SD cards and tiny flat products. Customized magazine...

DetailsAutomatic Side Label Applicator (with Stand)

LT2200

Automatic Side Label Applicator LT2200 can paste labels on the side of containers and products,...

DetailsAutomatic Top Labeling Machine

LT3000

Automatic top labeling machine LT3000 is a labeler that can be used for bags, boxes, bottles,...

DetailsAutomatic Side Labeler

LT3200

Automatic Side Labeler LT3200 is commonly used in food, medicine, household goods and cosmetic...

DetailsAutomatic Lipstick Labeler

LT320L

Automatic lipstick labeler LT320L is a customized labeler for labeling lipsticks with one tamper...

DetailsAutomatic Top Labeler

LT4000

The automatic top labeler LT4000 can continuously and accurately label a large number of labels....

DetailsAutomatic Two Sides Labeling Machine

LT4252

Our dual heads automatic top labeling machine, LT4252, is an advanced labeling device with...

DetailsTabletop Automatic Top Labeler

LT1000

The Tabletop automatic top labeler LT1000 is an economic, budget friendly piece of machinery...

DetailsTabletop Top Labeler

LT1100

Our LT1100, tabletop top labeler works with high efficiency, while provides perfect labeling...

DetailsTabletop Two-Sided Labeler (with two label applicator)

LT1252

Tabletop two-sided labeler LT1252 is designed specifically to fulfill labeling tasks with high...

DetailsAutomatic Round Bottle Labeler with Rotary Table

LR4300 / RT1080 / RT2080

This is the most convenient labeling machine with high stability and precise position. It has an automatic...

DetailsAutomatic Counting Capping And Labeling Line

NTM-420+NCA-410+NLT-210

Automatic Counting Capping And Labeling Line is design for packaging regular counting materials,...

Details

Automatic Top Labeler - Flat Surface Labeling Machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Automatic Top Labeler, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.