Automatic Two Sides Labeling Machine

LT4252

Two sides labeling machine

Our dual heads automatic top labeling machine, LT4252, is an advanced labeling device with two label applicators, and it’s designed to accurately label two stickers on the product or container at the same side. Hence, whether you need to attach multiple labels in specific configurations, or two different labels on products, LT4252 can handle. It's time-saving and efficient. We use PLC control system which can save multiple sets of memory parameter settings, so that you can change the product line at any time. What’s more, it can be easily integrated on automatic packaging production lines in food, biotechnology, and technology industries, improving the efficiency of your production lines.

Dual Heads Labeler

Our linear double-sided automatic labeler attaches two labels continuously on the same surface, saving time and increasing labeling speed. It’s suitable for a variety of flat containers and products, provides precise labeling results, showing a professional appearance.

LT4252 is widely used in the food and beverage, pharmaceutical, cosmetics and packaging industries, especially when the product needs to display many information on the packaging (such as brand, ingredients, nutritional facts, bar code or promotional content), the performance of LT4252 is more outstanding. Two label applicators of the machine can work separately, or work together as well. Its high accuracy make the labeling position on the product is perfectly aligned, and it can also flexibly use different labeling methods according to the requirements.

Its high attached degree improves the appearance quality of products

The labeling machine suits for various flat containers, such as flat bottles, aluminum foil bags, plastic bags, SD memory cards, contact lens boxes, shampoo, facial creams, paper boxes, credit cards, color boxes, coffee, preservation bags, cosmetics and electronic parts. The labeler ensures labeling precise and stable, allowing the product to display a professional and excellent appearance.

The LT4252 develops efficiency and productivity, avoiding repetitive or manual labeling, to make sure accurate position and alignment of stickers to improve the overall look of product labels. In addition, you can also choose advanced label detection, adjustable label speed and user-friendly control interface and other functions to make setting and operation more convenient.

The machine is designed for products have two stickers, it provides efficient and accurate labeling solutions. It not only saves time and labor costs, but also improves production efficiency and label quality.

Advantages:

- Improve efficiency

Two label applicators apply two labels on products which effectively saves time and improves the overall production efficiency. - Multi-functional

LT4252 can apply a variety of label combinations, such as primary, secondary labels and promotion labels, etc., providing diverse label options for products. - To meet the customization needs

Its two label applicators provide flexibility according to different label position needs. The labeler can apply to specific products, angles, directions or positions to meet the needs of individual products. - Cost savings

Dual label applicator design reduces labor costs. Reducing additional packaging machines or manual labeling work, and simplifying the overall labeling process.

Application & Advantage

Suitable Goods:

Food and Beverages: Bottles, cans and bags that have flat labeling needs, including sauces, beverages, snacks, condiments or packaged foods, chocolate, nuts, cashews, walnuts, cookies, candy, coffee

Pharmaceuticals and healthcare products: Medicine bottle, box or blister pack which paste important information on flat surface, such as dosage instructions, product name, warning and barcode. (painkillers, vitamins, calcium tablets, dietary supplements)

Cosmetics and personal care products: Cosmetics, setting powder, essence, hair conditioner, hair dye, lotion or perfume.

Cleaning supplies: Detergent, laundry detergent, disinfectant.

Industry and chemicals: Industrial chemicals, lubricants, solvents, oils or paints that need to be pasted safety regulations, product ingredients or instructions.

Technology and manufacturing: Components, electronics, memory cards which labeling for identification and branding.

Suitable Product Shape:

The labeled part should be flat and smooth surface, including the flat part of container, such as flat bottle, boxes and paper cards. The labeling positions are at the top, side and bottom of products. Single-side labeling.

Suitable Product Material:

Paper, glass, aluminum foil, plastic (PVC、OPP、PP、PE、PET), metals (tinplate, aluminum, stainless steel).

Suitable Labels:

Ingredient facts, bar code, promotion labels, fluorescent stickers, double sided tape, foam tape, waterproof stickers, transparent labels, nutrition labels, fragile stickers, thermal stickers, anti-counterfeiting labels, self-adhesive labels, temperature resistance sticker, warning labels, brand labels, expiry date labels, specification labels, serial number stickers.

Labeling Style:

Place products on conveyor. With accuracy control system, when product pass through label applicators, labeling stickers precisely on flat surface of products. Then, smoothing labels by sponge roller and brush to avoid wrinkles and bubbles.

Suitable Industries:

Food processing industry, Pharmaceutical industry, Manufacturing industry, Biotechnology industry, Technology industry, Cosmetic industry, Chemical industry.

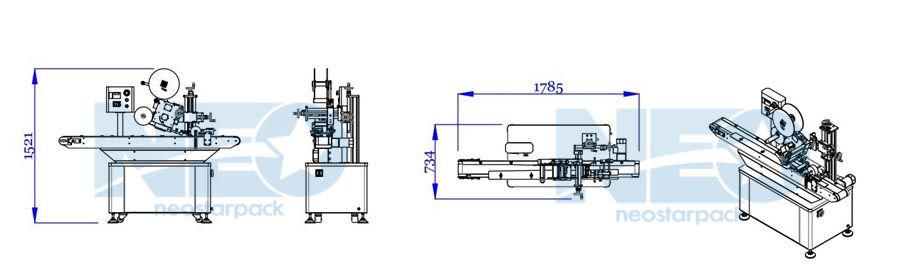

Machine Layout:

- Features

1. It’s suitable for flat thin products. You can choose top-pressing mechanism to effectively avoid the misplaced products in the convey process, and make the labeling result accurate.

2. Both label applicators are driven by Japanese motor, which keeps long-term stable operation.

3. Simple operation with colored HMI; providing Chinese and English language for users.

4. Memorize parameter function: saving labeling setting of different products, one click can start the production.

5. Adjust conveyor speed with continuous variable speed; automatic adjust capacity and improve efficiency according to product characteristic.

6. High labeling accuracy with micro-computer control system, which make the labeling result smooth without bubbles.

7. Japanese sensor precisely detects labeling position. You don’t need to adjust sensor when changing production line, saving time and cost

8. Synchronous smoothing function; closely attached labels to products, refined labeling.

9. It can equip with automatic feeding machine to reduce labor needs and develop productivity and safety.

10. Label 2 different stickers at the same time; saving time and space and enhance efficiency and competitiveness.

11. Adjustable labeling speed; to reach the best effect according to the product size and shape.

12. Automatic stop function, the machine will stop production when the stickers are used up or the target output has been reached, avoiding waste or mistakes.

13. Adjustable mechanism; moderately fine-tune the mechanism to match different size, position, angle and height of products.

14. It’s available to add feeding machine to increasing automation level.

15. Wear-resistant conveyor belt is antistatic.

16. Labeling delay function; fine-tune labeling position to fit different size of products.

17. Customized big size feeding tray is able to place more products and achieve quick feeding and labeling.

18. Dual base design comes with movable wheels and fixed base, which can be moved around to meet different production line requirement.

19. Modular components can match different products to provide a variety of optional accessories to meet diverse needs.

20. High-grade aluminum alloy guide rails are easy to adjust. The inner side of guide rail is low coefficient of friction, reducing abrasion and noise.

21. It’s made of SUS#304 stainless steel and aluminum alloy. The machine is easy to maintain and guaranteed.

22. The machine is easy to operate, maintain and clean, and in line with user-friendly operation.

23. Whole machine is designed and made in Taiwan with rigorous quality control.

24. User-friendly control interface: operate the labeler by HMI and button; fast setting and change parameters- Specification

Labeling Motor

Stepper Motor

Labeling Speed

30-60 pcs/min (according to product and label size)

Label Size

(Length) 10-300 mm, (Width) 10-100 mm

Label Roll

Inner Diameter 75 mm; Outer Diameter 300 mm

Accuracy

± 1 mm

Power Supply

110 or 220 VAC, 50/60 Hz

※ Actual product specifications may vary

- Option Accessories

- Collecting machine

- Automatic card feeder, bag feeder

- Transparent label sensor

- Top-pressing unit

- Japanese servo motor; labeling speed: 40m/min

- PLC system

- Hot stamping date coder, Date coder, Laser printer, Inkjet printer

- Automated Optical Inspection(AOI)

- Automatic Label detection system

- Introduce Movies

- Related Products

Automatic Top Labeler with Stand

LA2000

The labeler is a self-adhesive label labeling machine with flexible and diverse applications....

DetailsTop label applicator with conveyor

LT2100

Top labeling machine LT2100 is equipped with heavy duty table trolley, which is easy to connect...

DetailsAutomatic Top Labeler for Sd Cards

LT210SD

Top labeler for SD cards LT210SD is built for SD cards and tiny flat products. Customized magazine...

DetailsAutomatic Side Label Applicator (with Stand)

LT2200

Automatic Side Label Applicator LT2200 can paste labels on the side of containers and products,...

DetailsAutomatic Top Labeling Machine

LT3000

Automatic top labeling machine LT3000 is a labeler that can be used for bags, boxes, bottles,...

DetailsAutomatic Lipstick Labeler

LT320L

Automatic lipstick labeler LT320L is a customized labeler for labeling lipsticks with one tamper...

DetailsAutomatic Side Labeler

LT3200

Automatic Side Labeler LT3200 is commonly used in food, medicine, household goods and cosmetic...

DetailsAutomatic Top Labeler

LT4000

The automatic top labeler LT4000 can continuously and accurately label a large number of labels....

DetailsTabletop Automatic Top Labeler

LT1000

The Tabletop automatic top labeler LT1000 is an economic, budget friendly piece of machinery...

DetailsTabletop Top Labeler

LT1100

Our LT1100, tabletop top labeler works with high efficiency, while provides perfect labeling...

DetailsTabletop Two-Sided Labeler (with two label applicator)

LT1252

Tabletop two-sided labeler LT1252 is designed specifically to fulfill labeling tasks with high...

DetailsAutomatic Round Bottle Labeler with Rotary Table

LR4300 / RT1080 / RT2080

This is the most convenient labeling machine with high stability and precise position. It has an automatic...

DetailsAutomatic Counting Capping And Labeling Line

NTM-420+NCA-410+NLT-210

Automatic Counting Capping And Labeling Line is design for packaging regular counting materials,...

Details

Automatic Two Sides Labeling Machine - Two sides labeling machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Automatic Two Sides Labeling Machine, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.